Low vs High Vent Test Phase . . . . Where should the vent be positioned for best black powder ignition? Again, conventional flintlock wisdom is tested.

Up until this phase of the experiments the vent hole has been located level with the top of the pan. In those trials other variables were being examined. In this phase, the location of the ventis the variable. The lock plate has been adjusted to place the vent at the bottom of the pan. Actually the outside edge of the exterior cone is at the bottom of the pan.

Most shooters with this vent location use care to avoid covering the vent. In the first set of trials I primed three different ways:

1. Prime banked to the outside

2. Prime level in the pan (I tapped the fixture to level the prime.)

3. Prime close to the vent and covering it completely.

The equipment used was the same: computer, physics interface, photo cells, and the fixture for holding the barrel and lock plate. The location for the photocells remained the same. Priming charges were kept covered until they were used.

The amount of the prime for this test remains .75 grain of Swiss Null B priming powder. (This amount has been shown to be the most consistent in previous tests.) The methods used are the same as in earlier tests. The video link below shows the process. (This is the same video as in Part 5.)

Because I was worried about fouling causing unreliable data, every effort was used to eliminate it as a variable. As in the earlier tests, the following steps were used to prevent fouling from affecting the data:

Wipe barrel between shots.

Second cleaning rod designed to wipe the vent liner.

Pan brushed.

Pipe cleaner used through the vent.

Compressed air through the vent.

While these steps may seem unnecessary for normal shooting, I felt justified when trying to obtain meaningful data.

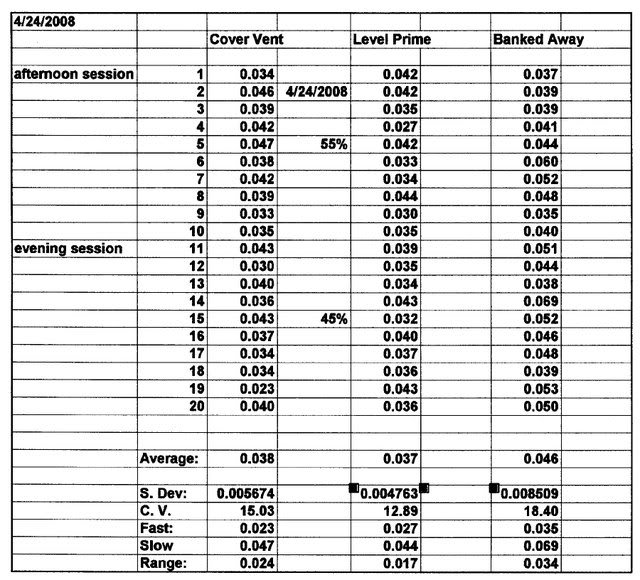

Below is the data gathered for the low vent test:

It is worth noting that the trials covering the vent and the level prime were as close as they were. I suspect that there is no statistical difference between these two variations. Both, however were faster than banked away. They were 15-20% faster, in fact. I’ll draw no further conclusions until the high vent location is timed.

High Vent Test Phase

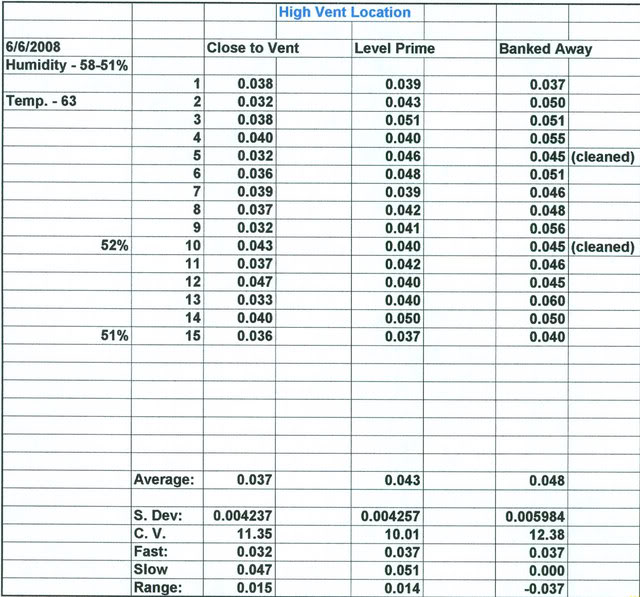

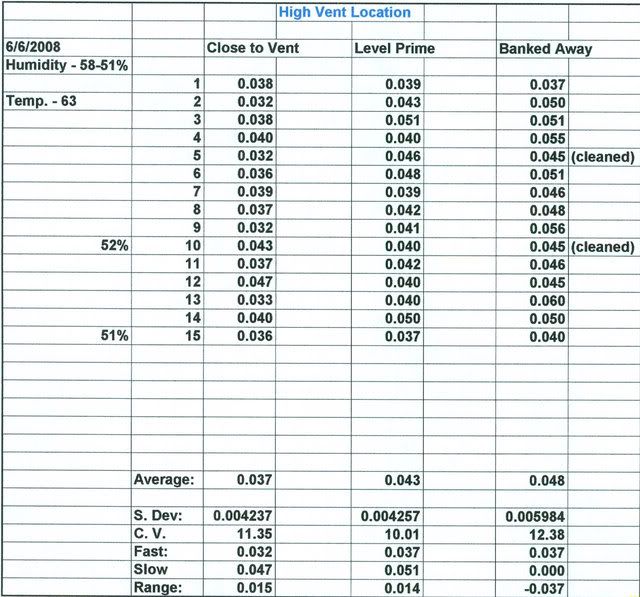

As I worked on the high vent phase, humidity became a concern. I was uncertain if I could maintain a comparable humidity when this phase was done. Earlier testing had been done with humidity in the 50-60% range. I waited for weather to help me, but found that by using an air conditioner in the garage I could keep the humidity within this range. Humidity at the beginning of the test was 58% dropping to 51% as the testing concluded. Temperature throughout testing was 63-64 degrees.

The only variable in this phase was the location of the vent. The lock plate and pan were rotated to place the vent as high as possible. The bottom edge of the exterior cone on the vent was well above the level of the pan. Please note the photo showing the vent hole.

The procedure was to time 15 tries with each of three powder locations in the pan – just as I did in the low vent tests. The tries were alternated as follows: powder banked away, level prime, and as close to the vent as possible. In this last location, I had intended to cover the vent, but .75 grain of powder was not enough with the vent located this high. I considered increasing the charge to 1.0 grains, but concluded that it would introduce another variable. I decided against that and used a pencil eraser to position the prime as close as possible.

After each location was timed 5 times, I removed the barrel and cleaned everything. Then I timed the next series. After 10 times I again cleaned, and then timed the last group.

The chart that follows shows the data gathered. As happened in the low vent trials, banking the powder away was slower and less consistent than level or close to the vent. Close positioning of the prime was decidedly faster and more consistent.

Conclusions:

These conclusions are those of the experimenter. You may have different opinions.

I wish to point out that every trial produced a report that sounded as one sound. The fastest (.032) and the slowest (.060) sounded the same. Even though one was almost twice as fast as the other, the sounds were indistinguishable. So my first conclusion is that the human eye and ear are terrible tools to use to evaluate flintlock performance. If differences can be determined by human senses, then the trial was indeed very slow.

The idea to bank powder away from the vent to improve flint performance is flawed thinking. In every test I conducted, the banked away trials came in last. Percentages varied, but banking the powder away was always slower. I found no evidence to support the old “bank the prime away from the vent.” (In the low vent test, banking powder away was 17% slower; in the high vent test, banking powder away was 23% slower.)

The idea that one should not cover the vent with priming powder because of having to burn through the vent instead of flashing through seems equally flawed. While I did not try to fill the vent, covering the vent did not cause slower times. The closer I could get priming to the vent, the faster and more consistent the results. In fact the consistency I found in positioning the priming powder close to the vent occured at all vent positions – low, level, and high.

The last conclusion involves the reason for this whole experiment – proper location for the vent in relationship to the pan. I found that the location of the vent in relation to the pan is far more forgiving that we have believed. Tests when the vent was extremely low or high both gave quick reliable ignition. A look at the chart below shows that all vent positions gave fast ignition when primed close to the vent (This is what we learned in the preliminary tests.) Also all vent positions gave uniformly poor performance when the priming powder was banked away from the vent.

————————–Banked way—————-Level Prime—————-Close prime

Low Vent—————–.046—————————.037—————————-.038

Level Vent —————.043—————————- * —————————–.036

High Vent—————–.048—————————.043—————————-.037

*I did not time level priming when testing the level vent/pan position.

I began this series of test thinking that the big variable would be the vent location. However, I am now concluding that it is of minor concern compared to the location of the priming powder in the pan. I still like a vent level with the plan flat won’t loose sleep over a pan a little high or low.

All of the work represented here was based on igniting the powder “artifically” using a red-hot copper wire. This was done intentionally to remove the variables in amount, quality, and location of the sparks. In reality the flint shooter must manage his lock to minimize these variables. Regardless of what the experiments show us, the shooter must place priming powder where his sparks will land. Time with his gun will determine this. However the shooter need not be afraid of priming powder too close to the vent – that is to be encouraged. It is far better to have the prime too close than too far away.

Pan Vent Experiments — Introduction

Part 1 — Black Powder Ignition Characteristics

Part 2 — Initial Pan Experiments

Part 3 — Photography through the muzzle

BlackPowderMag.com Flintlock Rifles and Black Powder Guns

BlackPowderMag.com Flintlock Rifles and Black Powder Guns