Determining the amount of black powder to be used in testing. Since flintlock pans are of different size, I felt that this was a necessary step in our process.

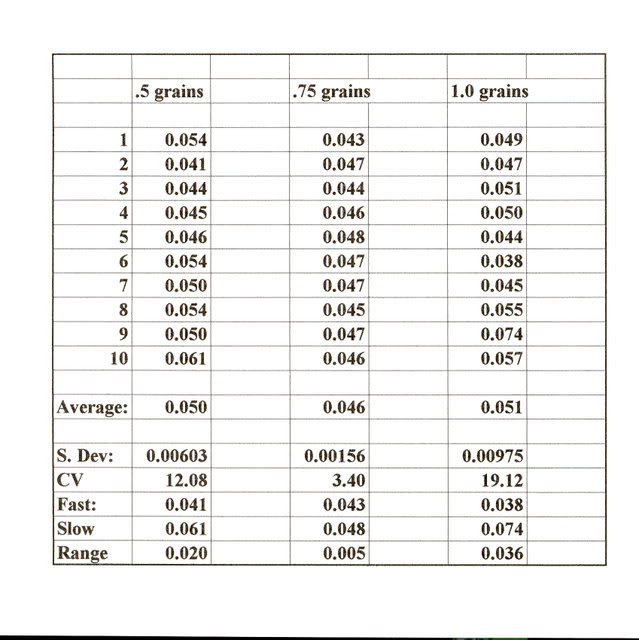

In this phase of testing I timed different amounts of priming powder. Ten amounts each of .5 grains, .75 grains, and 1.0 grains of Swiss Null B priming powder were weighed to the nearest tenth of a grain. These were timed in the fixture to see if varying the amount of prime affects the speed or consistency.

The fixture allowed the barrel to be rotated to vertical to load 15 grains of Swiss fffg for the barrel powder. The barrel was then rotated to level and the pan primed. Photo cells were checked to make sure they are pointed at the pan and the muzzle. The last step was to make sure the computer was ready. The pan was ignited with a hot copper wire and the readings recorded. The barrel was wiped between trials.

Photos of the fixture are shown below.

These two fixture photos also show the range of movement that can be used to test the location of the vent hole in relation to the pan. The top photo shows the hole in it’s lowest location, while the bottom photo shows highest location. For all tests so far, the vent hole has been centered on a line level with the top of the pan.

The graph below shows the trials with the three different priming powder amounts:

In evaluating the results of this test, I found Joe Sharber to be of great help. Joe, a fellow blackpowder fan with statistical experience, provided help with the number crunching. He pointed out that there is no statistically significant difference in the average ignition times. However he also noted that the variability or standard deviation was statistically significant.

Joe suggested that the term “Coefficient of Variation” * may be of value as a measure of consistency. The CV listed in the chart helps to show the advantage in consistency of the trials done with .75 grain priming powder. Because of this .75 grain will be the powder amount used in future tests.

* Coeficient of Variation is defined as 100 x (standard deviation divided by the mean). It is given as a percent. My thanks to Mr. Sharber for his assistance.

Pan Vent Experiments — Introduction

Part 1 — Black Powder Ignition Characteristics

Part 2 — Initial Pan Experiments

Part 3 — Photography through the muzzle

Part 5 — Timing Powder locations in Pan

Part 6 — High and Low Vent Experiments

Leave a Reply

You must be logged in to post a comment.