Do you live in a lead-free hunting zone? Are there alternatives for the traditional muzzleloading hunter? BlackPowderMag examines one possibility.

Recently I received a quantity of ITX non-lead balls made to be fired in a muzzleloading rifle. The maker is Continuous Metal Technologies Inc located in Ridgeway PA. Brad Clinton is the contact person. The company produces non-lead projectiles for hunting applications. If, for a variety of reasons, hunting with lead becomes unlawful, these products may prove to be a viable alternative.

You can see a belt running around the ball. This ball measured .487 when not measuring the belt. Around the belt it measured .002″ larger. We seated the ball with the belt level – (with the belt thought of as the equator, the North pole was up). We speculate that if the belt went in slanted, it might be possible to damage a land.

This week Steve Chapman and I worked on testing the non-lead ball in a .50 caliber muzzleloader. Two samples were available: .487 and .490. We planned to test both. The goal was to determine the potential for accuracy with a non-lead patched ball.

The rifle used was a light bench/x-sticks gun, which Steve used to set a National muzzleloading record. The barrel is made by Green Mountain (1 in 70” twist) and is equipped with target apature sights. When firing the record target Steve used .495 lead balls patched with Teflon. The barrel was wiped between shots.

Before heading to the range I weighed out the balls. The .487 balls ranged from 156-159 grains. I sorted them into groups to minimize the weight differences. The same was done to the .490s. They weighed 152-155 grains – less than the .487s. I don’t understand this. The weighing was done in the same session on the same surface with the same scales.

At the range while Steve was sighting in with lead balls, I pushed a .487 patched ball through a barrel stub. We wanted to check on patch cutting with the harder ball. With this barrel stub the ball cut patches with every patch material we tried. We determined the cause to be the crown on the barrel stub. My reason for reporting this is that if your barrel has any tendency to cut patches, this very hard ball will increase this tendency. We saw NO deformation in the ball, no matter how tight a patch we tried.

We then tried to seat a patched ball into Steve’s target barrel, pull it out by the patch material, and look at the ball and patch. Instead the patch material tore off, leaving the patched ball in the barrel. We removed the nipple, added a squib powder charge, seated the ball, and fired it out. We concluded that if one dry-balls with one of these, pulling the ball will not be an option. You will have to be able to get powder behind the ball to remove it. It’s possible that if a ball was seated against the breech plug, one might need to unbreech the rifle to remove it. (We did not try using a CO2 discharger; that may or may not have worked.)

Not wanting to risk Steve’s barrel with a cut patch, we started with a 20 gr load and worked our way up 20 grains at a time, looking at patches for cutting. We determined that with the excellent crown on Steve’s barrel we could use pocket drill with Murphy’s oil soap at normal velocities with no patch damage. (Later we used Teflon moistened with spit with equal success.)

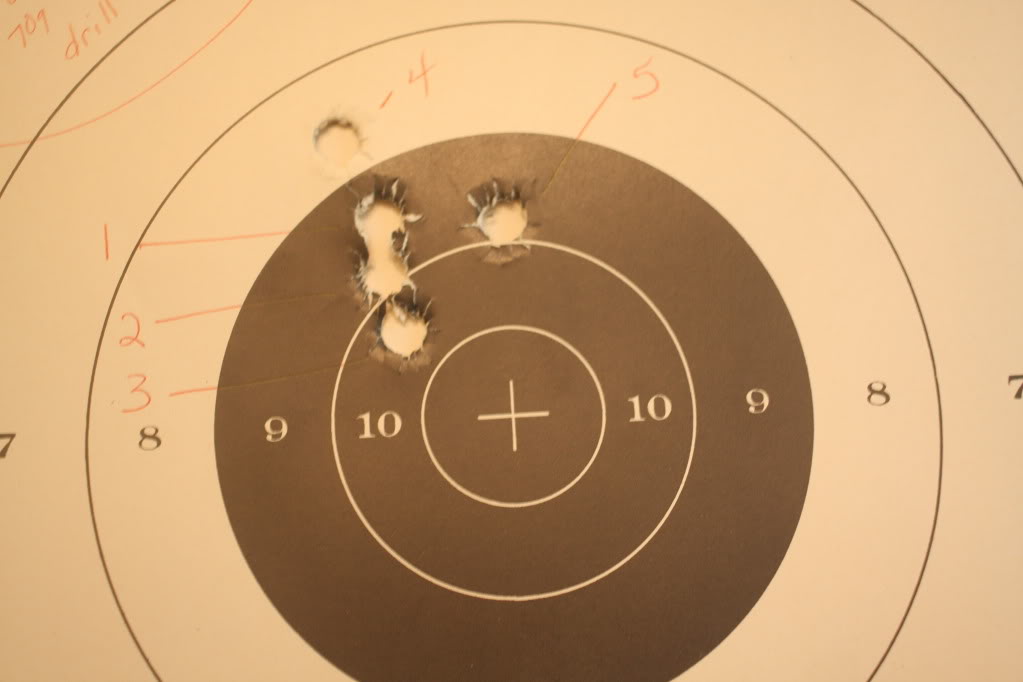

At 50 yards, Steve used 70 grains of Swiss ffg behind the .487 ball and pocket drill w Murphy’s oil soap full strength. Compared with a normal lead ball, it chronographed faster, but elevation on paper was the same. This group measures 2 inches.

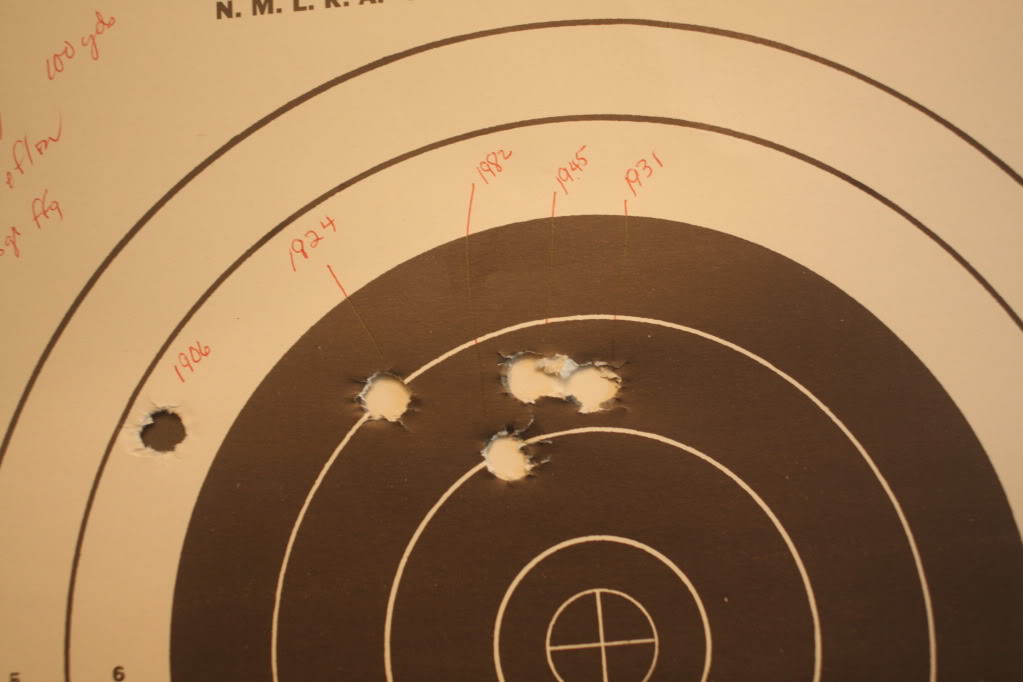

At 100 yards, Steve used 85 grains of Swiss ffg, .487 ball. And pocket drill w Murphy’s oil soap full strength. We also tried Teflon with equal success. This group measured 4 inches.

We feel that the non-lead ball is capable of hunting accuracy and informal off hand target work, but would prefer lead ball for serious offhand or target work that allowed a rest – such as bench or X-sticks. We feel that it will take a serious competition shooter to detect a difference. The added complications with a dry-ball during a competition match may be a factor weighed by some as well.

In order to make a valid comparison, we included a target that Steve shot at Friendship that shows the potential of the patched lead ball with Steve behind this barrel. This target, shot at 100 yards, measures 1.875″ and holds a National record. It was shot with Teflon patching. That is the reason Teflon patches were included in the testing above. Teflon does require wiping between shots, and pocket drill would be the reasonable choice for a hunting load.

Today, wind was our biggest variable, but on two occasions Steve clover-leafed three balls with a lead ball when doing comparisons. He couldn’t do this well with the non-lead ball, but hunting accuracy out to 100 yards is quite acceptable. We expected the non-lead ball to strike lower on the paper at 100 yards, but it did not. I expect that being lighter; its higher muzzle velocity (50-60 fps) may have helped. At distances beyond 100 yards the non-lead ball may drop faster, but we did not shoot beyond 100 yards.

We do feel that shooting this non-lead ball places different responsibilities on the shooter. Dry-balling with a lead ball is a minor inconvience, compared to dry-balling one of these. Good muzzle crowns become much more important. This is not to say that a good crown isn’t important with a normal lead ball, but it is huge with non-lead. Strong, tough patch material is vital with this ball as well. We don’t know what damage might be done if one shoots a ball this hard with a patch that is cut as it enters the barrel. We were prepared to stop the test if that happened rather than risk Steve’s barrel.

We did not test the larger .490 ball for the reason mentioned above. It cut both Teflon and pocket drill when we tried it. The cutting was not the fault of the crown because we worked all day with the smaller ball and with the lead ball with no cutting. Obviously special care is required in choosing the patch material for the non-lead ball.

In our testing we were concerned with accuracy and made no attempt to evaluate the effectiveness of the ball on a game animal. However, based on our accuracy testing, we conclude that the non-lead ball is a viable alternative for hunting use within the range we tested. We speculate that the harder ball will deform less and penetrate deeper than a lead ball. Accuracy is quite acceptable within the ranges that a traditional rifle would be used. As mentioned above, loading and patching techniques are different from handling a lead ball. The shooter will need to adapt to handle the harder ball in order to protect his barrel.

For further testing, we suggest that a ball that measures .015 – .020″ less than the bore (on the belt) may help to make the ball more forgiving to shoot. For .50 caliber, a belt measurement of .482-.485″ might be worth considering. Obviously this will mean a very thick patch, but may help to protect the rifling.

The following is contact information:

Continuous Metal Technologies Inc. 439 W Main Street Ridgeway, PA 15853 814-772-9274

Brad Clinton email: bclinton@powdered-metal.com

Leave a Reply

You must be logged in to post a comment.