[box type=”note” align=”aligncenter” ]Reprinted from MuzzleBlasts September 1992 by Larry Pletcher —- This article is the second in a series of three reprinted articles that measure a flintlock’s ability to ignite black powder. R. E. Davis Company, black powder vendor in Pleasantville, Ohio provided the flintlocks used in this article.[/box]

Most of the testing and timing of flintlocks completed at this time has been done with modern reproduction locks. Because of their value, original locks should not be subjected to an extensive number of tests. Lock makers of today can’t help wondering how their work compares with the work done during the flint era. The Journal of Historic Armsmaking Technology Vol. IV has attempted to shed some light on this subject. The originals tested in Vol. IV can now be used as a benchmark by which reproduction locks may be compared.

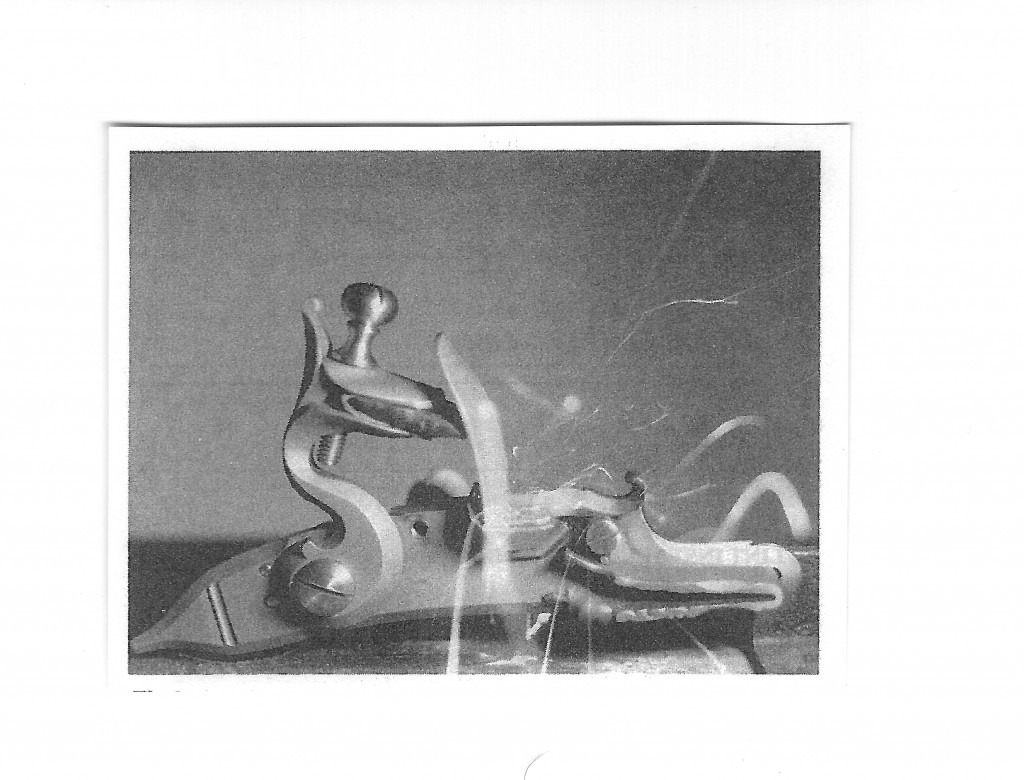

The three flintlocks tested in this article were made by R.E. Davis Company in Pleasantville, Ohio. The first, the Davis Yeager lock, which has an unbridled frizzen and a fly in the tumbler, can be found on many Yeager styled reproductions. The familiar banana shaped lockplate measures 6” by 1”. The lock would look at home on early German styled arms. Its Davis catalog number is #017.

The second lock is described by Davis as an Early Large Flintlock. It, too, is a large lock measuring 5 9/16” by 1 1/8”, and has an unbridled frizzen and a fly in the tumbler. The lock has Germanic styling and would by appropriate on transitional pieces. Its catalog number is #040.

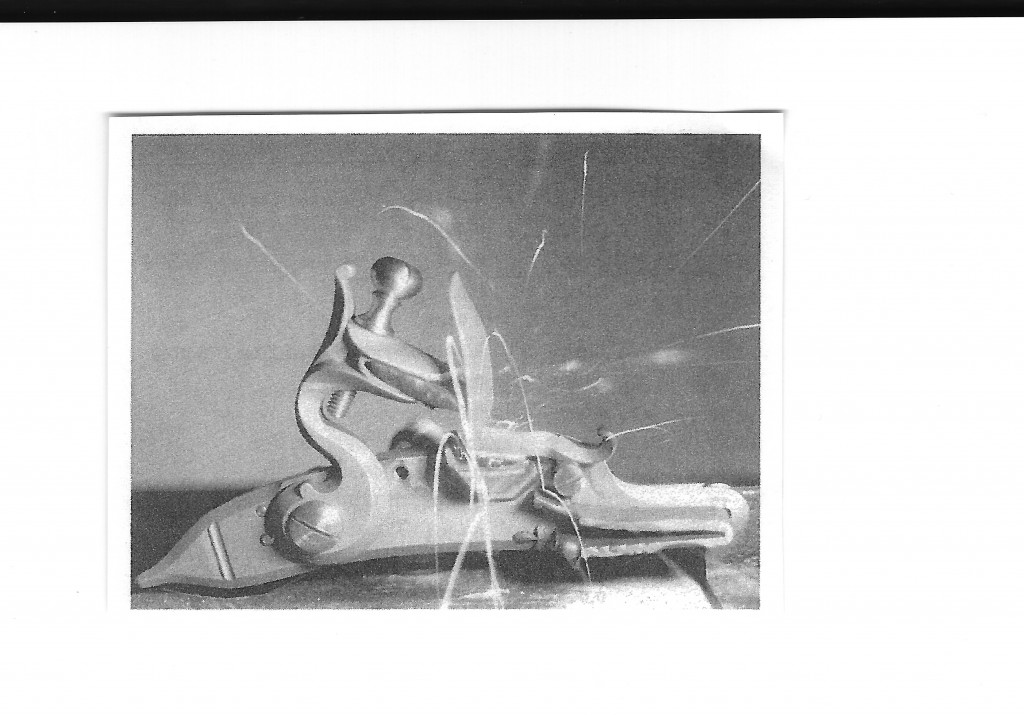

The third lock tested in the Twigg lock (catalog #201). This English styled lock is 5 5/8 inches long with a bridled frizzen on which a roller has been installed. A stirrup is used on the tumbler. A pronounced camming effect can be felt as the cock is drawn back with little pressure required to move from half to full cock.

Testing was done with a measured amount of Goex 4Fg blackpowder. (The powder was stored at room temperature in a dry environment). Both flint and frizzen were cleaned between trials and flints were knapped when any noticeable change in their operation developed.

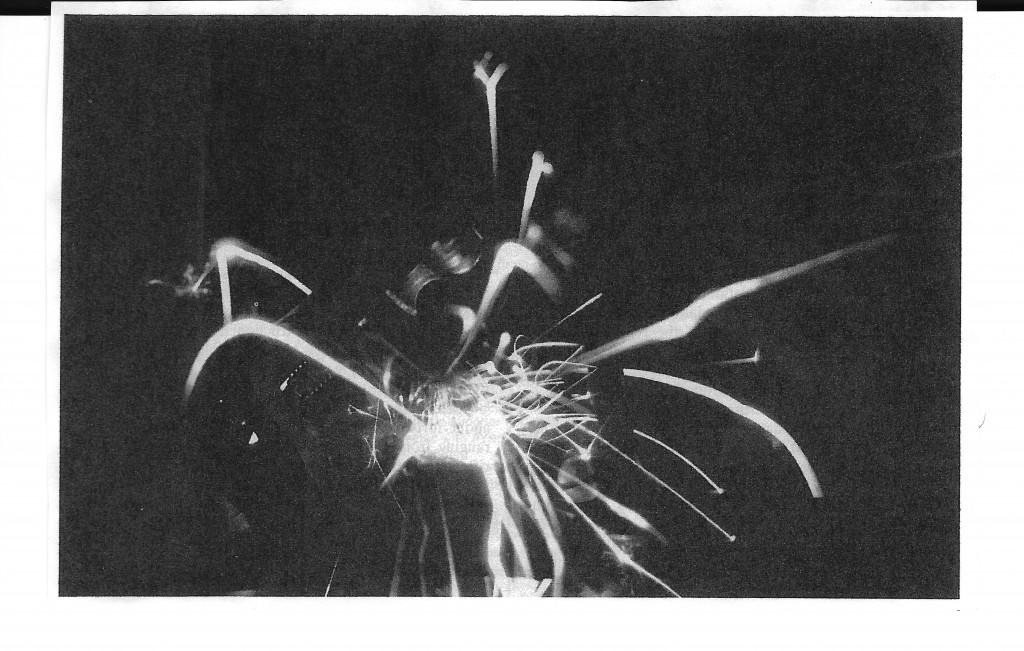

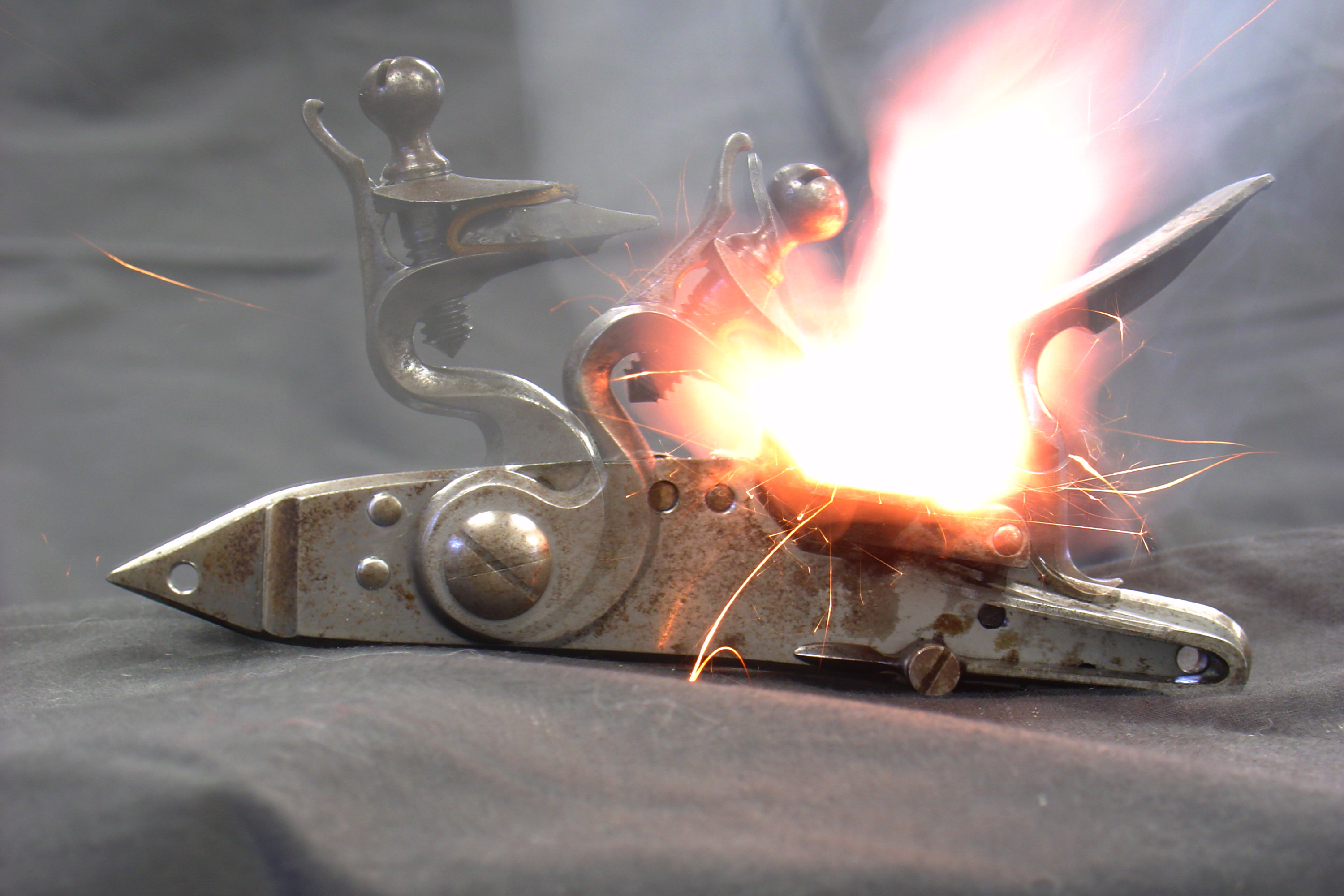

Photo 1

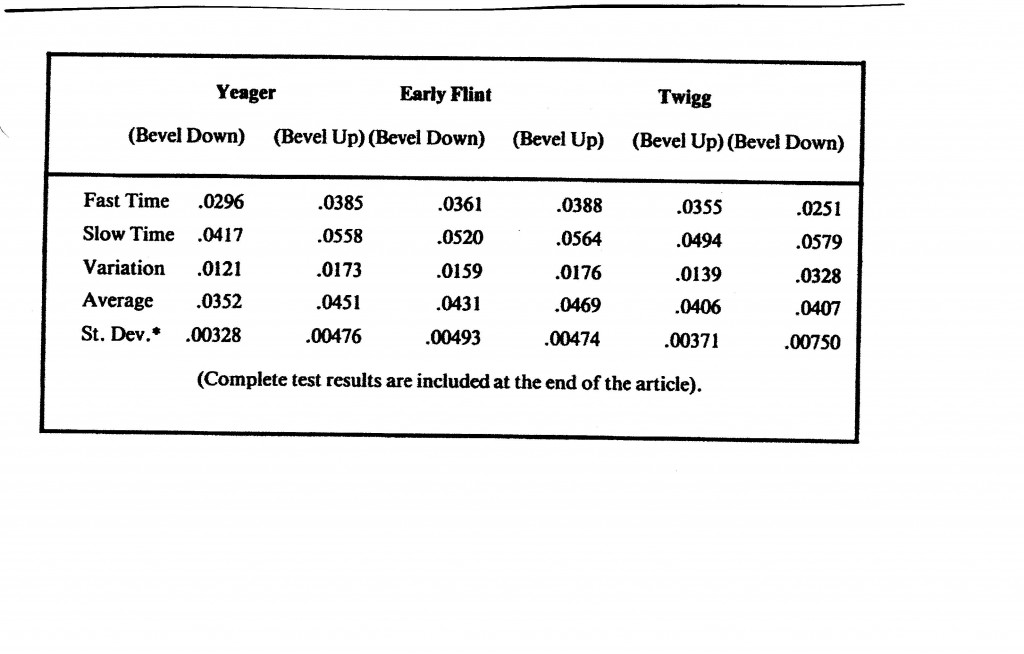

Since previous experience indicates that locks may show a preference for a particular way on installing flints, I again tested each lock with the flint bevels installed up and down. A series of 20 tests was conducted in each configuration. The complete test for each lock is in the appendix at the end of the article. The test results are summarized in the following chart:

Fig.1

The test summary showed that the first two locks had a preference for the flint to be installed with the bevel down. This was especially true for the Yeager. Its average, variation and standard deviation were all improved substantially with the bevel down.

Photo 2

While the difference in performance was too small to be detected by human limitations, I would shoot this lock with the bevel down. My reason would be more for the improved variation than for the improvement in speed. I was very impressed with the Yeager’s variation and standard deviation.

Photo 3

The Early Large Flintlock was slower than the Yeager. Its average, variation and standard deviation were equal to the Yeager with the bevel up. This lock preferred the bevel down, but not to the same degree as the Yeager. I would probably shoot this lock bevel down, but I’m sure the difference would not be detected when firing. Its performance was quite satisfactory.

In analyzing the Twigg lock, one can see that the average times were almost identical. However, positioning the bevel up brought about the best standard deviation. The lock was almost twice as consistent this way. I would shoot this lock with the bevel up to take advantage of the improved standard deviation. Because the Twigg likes a long flint, I had to make sure the flint installation did not allow the top jaw screw to hit the frizzen. I liked this lock almost as much as the Yeager.

When shooters discuss the speeds of various locks on the market, one often hears the theory that large locks are slower than small locks because there is more mass to accelerate. While this theory may hold some truth, the Yeager looks like the exception. In spite of its size, the Yeager (with the bevel down) performed as well as a number of smaller locks I have tested. With the flint installed bevel up, its performance was slower and more nearly what I would have expected of a larger lock.

* * *

The accompanying photos allow another statistic to be measured. I attempted to calculate the speed of the flint as it travels down the frizzen by measuring the distance the flint traveled in photos. A proportion was set up using the following format:

Fig .2 – Proportion used to calculate flint speeds

Photo Frizzen Length Photo Flint Travel

————————- as ———————–

Actual Frizzen Length Actual Flint Travel

Fig.3 – Speeds of flint desending the frizzens of the Yeager and Twigg

Lock: Upper Flint: Lower Flint:

Yeager 15.6 ft/sec 12.1 ft/sec

Twigg 13.2 ft/sec 20.7ft/sec

The Yeager flint is apparently slowing down as it travels down the frizzen, while the Twigg’s camming effect allows it to overcome friction and actually accelerate. This did not prevent the Yeager from out-performing the Twigg both in speed and consistency, however. Apparently, raw flint speed is not the answer to lock performance. So far, I have tried to measure flint speeds on only three locks. I hope tests such as these can be substantiated by additional testing.

I hope these lock-timing experiments will cause us to think about the factors that cause locks to perform well. Obviously, there are considerations which we have not measured and perhaps can never isolate. Maybe by experimenting with different modifications, we can identify some characteristics of successful locks. In a future article I will report on modifications done to one of the popular locks on the market.

Leave a Reply

You must be logged in to post a comment.