Lancaster County — The Search for Samuel and Henry Pletcher

Our search begins with tracking down a rumor that the name “Pletcher” was carved in a wall at Valley Forge.

We stop at the Mennonite Historical Society.

Valley Forge – Tuesday, May 26

Our first day began with a drive from Lancaster to Valley Forge to look for a “Pletcher” reported to be carved in a wall there. We wondered if it might have been Henry who was a member of the Lancaster Co. Militia. We first went to the Welcome Center and wandered through a number of elementary school classes on field trips. That brought back some memories good and bad.

I asked about any lists of soldiers that might have been at Valley Forge and was led to a computer data base available to visitors.

We tried all versions of the name Pletcher but found nothing. We then found out that all the soldiers at Valley Forge were Continental Soldiers – no militia groups were quartered there. That ruled out Henry’s unit. Also we were told that no original huts existed, ruling out the likelihood of a Pletcher name being found.

We used the CD to follow the car tour of the grounds. While Valley Forge is an interesting historical site, we struck out when looking for family history.

Above is another of the log huts built to General Washington’s specifications. The huts here are modern reconstructions.

Below is the stone house that housed Washington and his staff. He rented this house and used it as the 1770’s version of the Pentagon.

Here is one of the rooms Washington used.

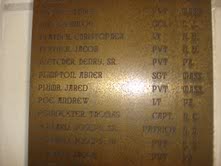

A correction needs to be added here. Lynn De Grave is a Pletcher relative living in France and supplied new information to me about the Henry Pletcher name at Valley Forge. We were looking the wrong place. Lynn found Henry’s name in the carillon tower at the Washington Memorial Chapel. Henry Pletcher Sr is on the DAR memorial list. Below are photos of the location:

We returned to Lancaster in the afternoon and stopped at the Mennonite Historical Society on US 30. There we found a wealth of information about the Pletchers. One book specifically was a great help. It contained some material which we already had, but much was new. Because it was near closing time we decided to begin our second day there to continue looking. That evening we contacted the author by phone and requested a copy of the book. While a delay is expected because of health issues, the author agreed to produce a copy for us.

Lancaster – Wednesday, May 27

Wednesday we began at the Historical Society and found additional information in a periodical. The article was on the Schenck family connection. It included information that will be of help when we go to Howard PA. The book store upstairs had back issues so we bought a copy. We also went through the Pletcher book and made notes. I brought my camera in and took photos of important pages. We realized that since we had a chance to speak with the author the night before and request a copy we only photographed important pages.

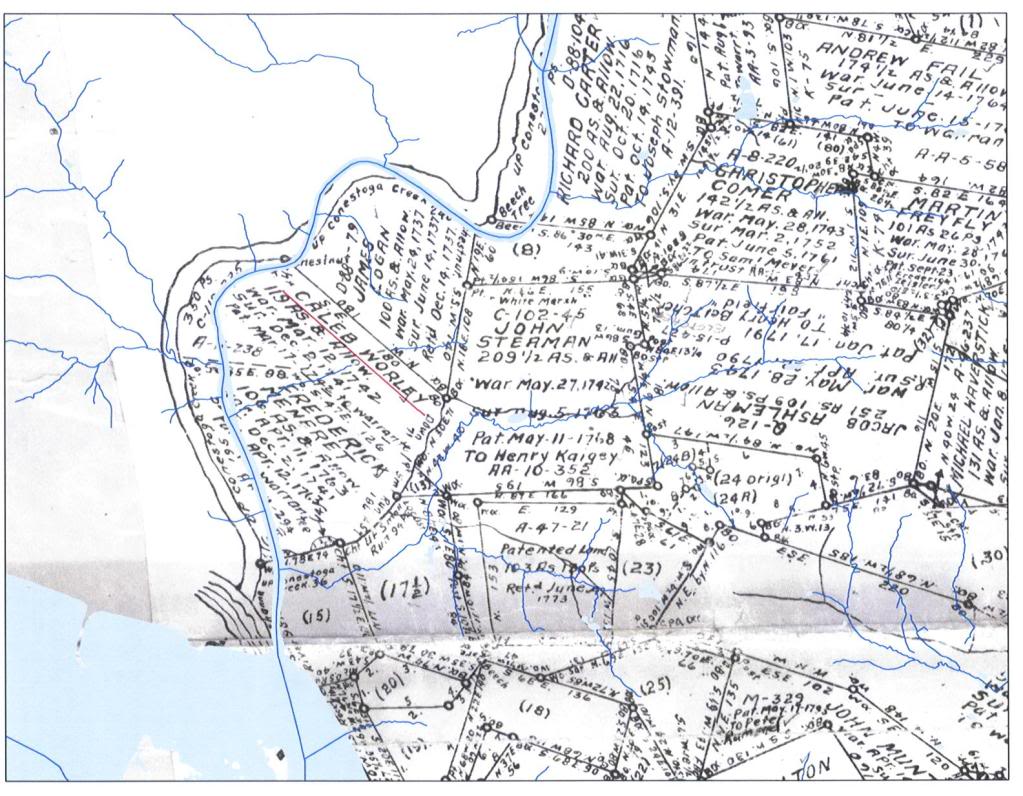

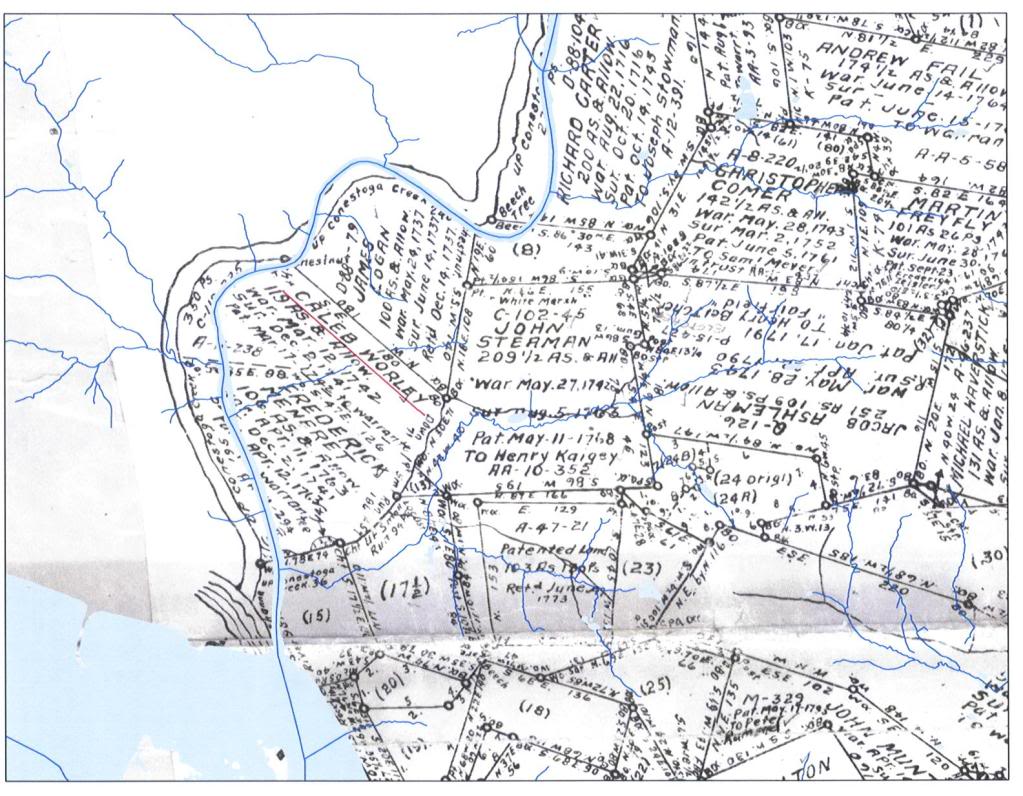

Our next stop was the Court House. We wanted to see if we could find a copy of the deed for Frederick Maynard’s property. His farm would have been the farm where Samuel and Henry grew up. What we found was a copy of the transaction when Frederick bought the property. Taking this to another desk we found a map from the 1700’s that showed the area with owners listed. A modern map was superimposed, showing modern roads and current path of Conestoga Creek.

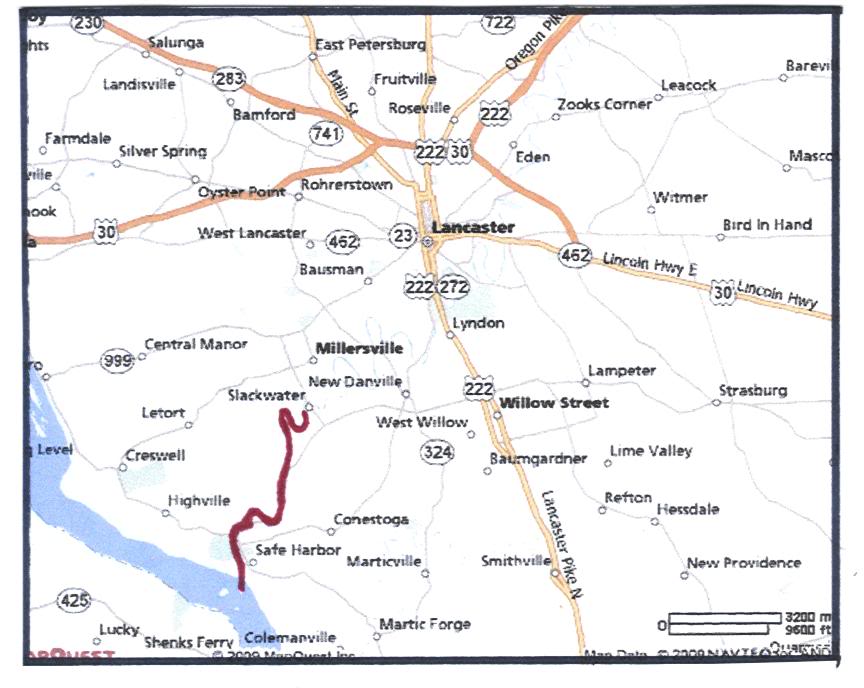

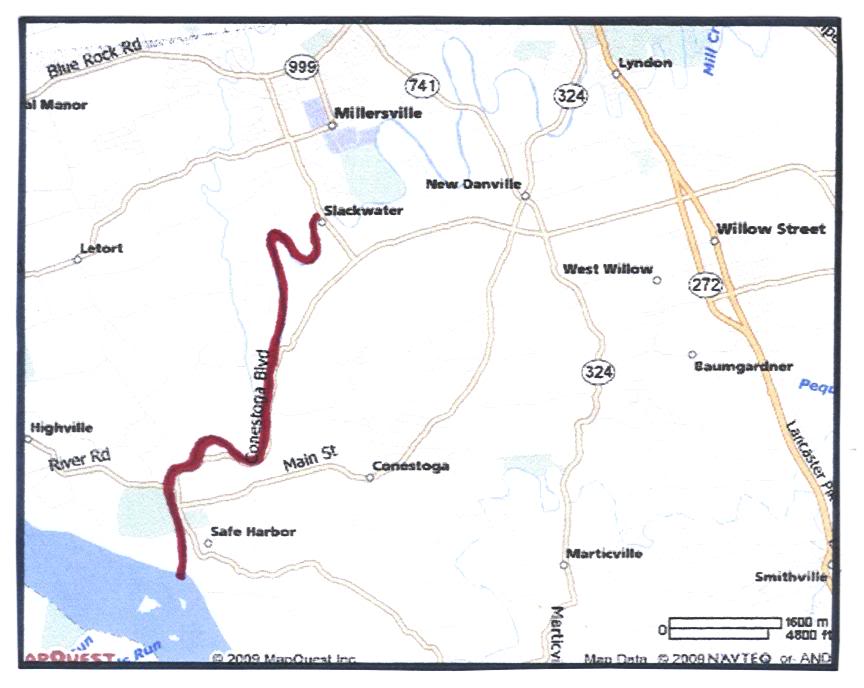

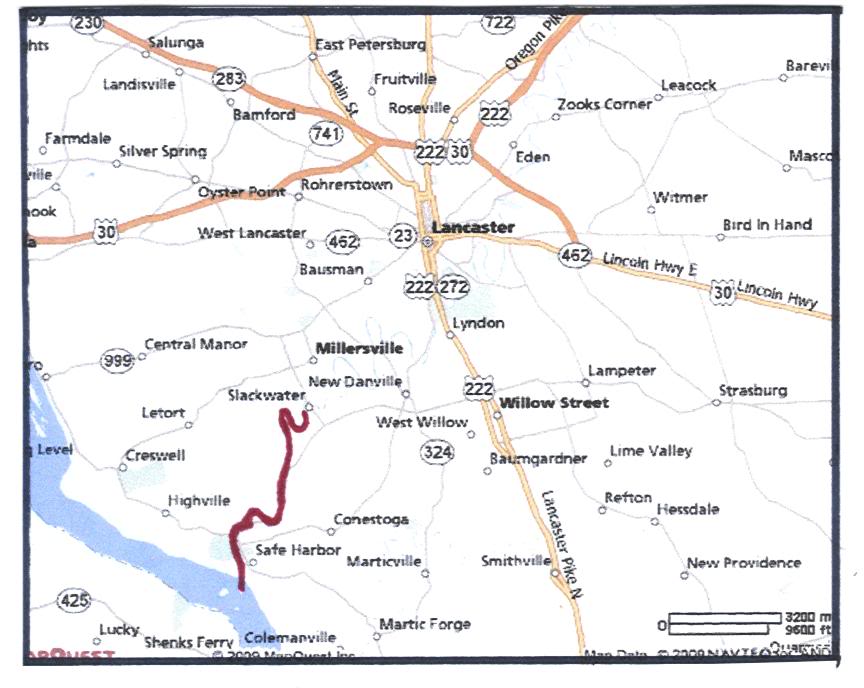

Below is a map of Lancaster. Conestoga Creek is marked in red near its mouth.

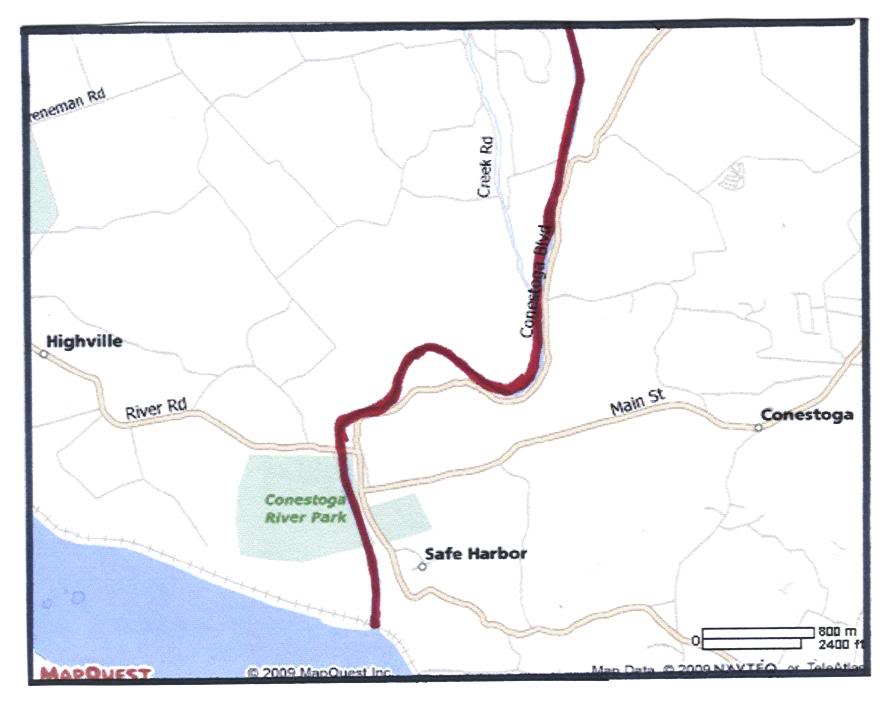

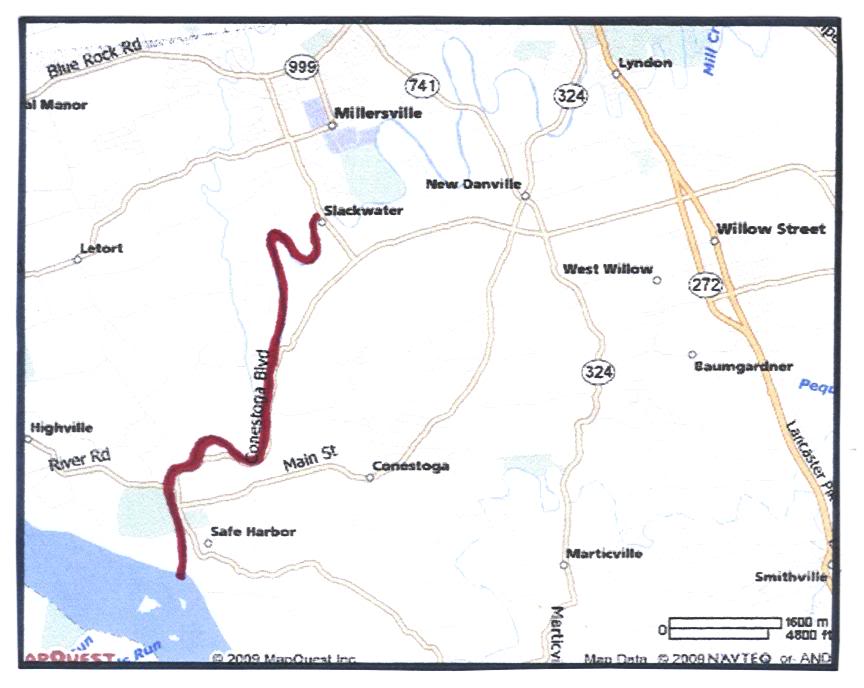

Below is the same area enlarged. Conestoga Creek is again marked in red.

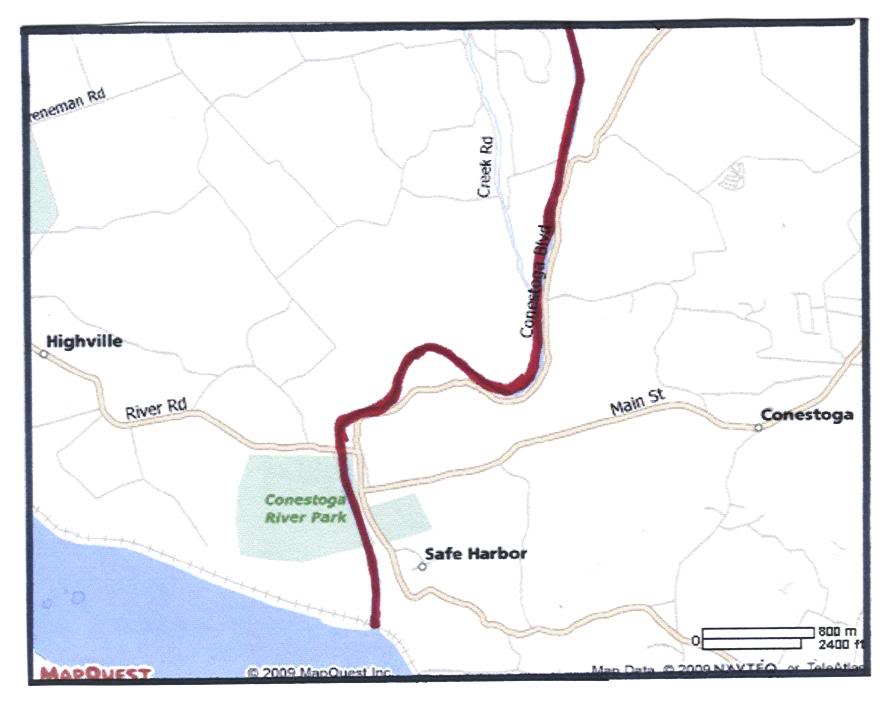

Below is a map showing Conestoga Creek. The bends in the creek help to locate Frederick Maynard’s farm.

Below is the map showing the property that Caleb Worley sold to Frederick Maynard. This is the farm where Samuel and Henry Pletcher grew up.

Below is the map showing the property that Caleb Worley sold to Frederick Maynard. This is the farm where Samuel and Henry Pletcher grew up.

After lunch we headed for Frederick Maynard’s farm. We traveled to Safe harbor along the Susquehanna River and followed the road along side of Conestoga Creek. With the creek to our left and Maynard’s property to our right we followed the road through the western part of the property eventually finishing the loop and ending up back at Lancaster. Along the way we stopped and took pictures – mostly along the creek. One bridge crossed Conestoga Creek at a shallow riffle.

We expect folks would have forded the creek here because of the shallows. The bridge was added here much later because the roads would have led to the ford.

Howard – Thursday, May 28

We left Lancaster and headed for Howard hoping to use the same route that Samuel would have used in 1790 when he made the trip by wagon. He followed the Susquehanna River north along the east bank until he reached the Juanita River. Then he followed the Juanita River west and north until he reached the valley where Howard would later be founded. For us it meant following RD 322 most of the way. We used RD 150 to enter the valley and followed it along the north side of the valley until we reached Howard. The reservoir dominates the view of the valley. The town of Howard is protected by a large dike on three sides. The unprotected side of Howard is where Gap Run comes into the valley.

We followed the road through Howard toward the Gap. As we left town the sides of the Gap, the road and creek took all the room. The road was closed over by trees.

Maybe this the way Gap Run looked to Samuel in 1790.

As the Gap opened up, we turned around and went back into town. We decided to try the Post Office, hoping to find the cemetery. The Post Master did not know, but an old codger coming in had good advice. He told us to check with Carolyn Hollar because she was a Pletcher and knew everybody. He also suggested that we stop at the Fire Department. He said, “There are always old codgers over there.”

We tried Mrs. Hollar but got no answer at the door. We went to the Fire Dept. next. No one was there, but a car drove up with Earl Thompson and his wife inside. Earl was full of information. When I asked about Henry’s cabin, he said, “I know where that is, but it’s under water. He told me to stand on the dike at the end of Main Street and look left. He also told me that Main Street was the old 220 that my text described.

These next two photos look out over the lake where Earl described the cabin.

Mrs. Thompson told us that in April the reservoir was drawn down to the creek level. At that time you could see exactly where the creeks were and use them to locate other positions. They both encouraged me to walk the dike and get an idea about the various submerged locations. They also said to go back Mrs. Hollar. She would be invaluable.

As I walked along the dike going back to the car, I lined myself up with Main Street (Old 220) and looked back across the dike. I saw an old, moss-covered asphalt lane. I was looking at Old 220 as it disappeared into the trees on its way down into the reservoir.

Remembering that Henry Pletcher’s the first cabin was near where 220 crossed Gap Run, I walked as far as I could into the woods following the blacktop. Deeper into the trees I could hear Gap Run off to the right. I was probably within 50 yards of Henry’s first cabin.

Besides the cabin mentioned above, there were other cabins that Samuel and Henry built. All traces of them are below the water level. I asked about a building that might have housed the distillery that Samuel ran briefly. No one knew where that might have been.

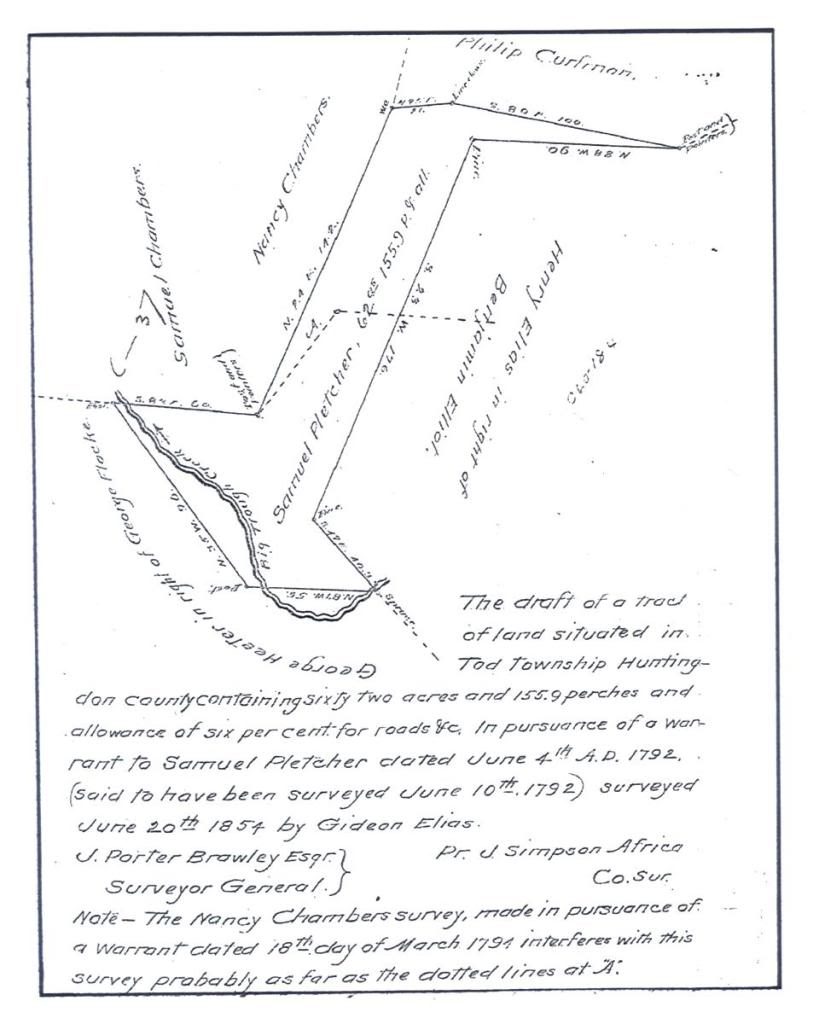

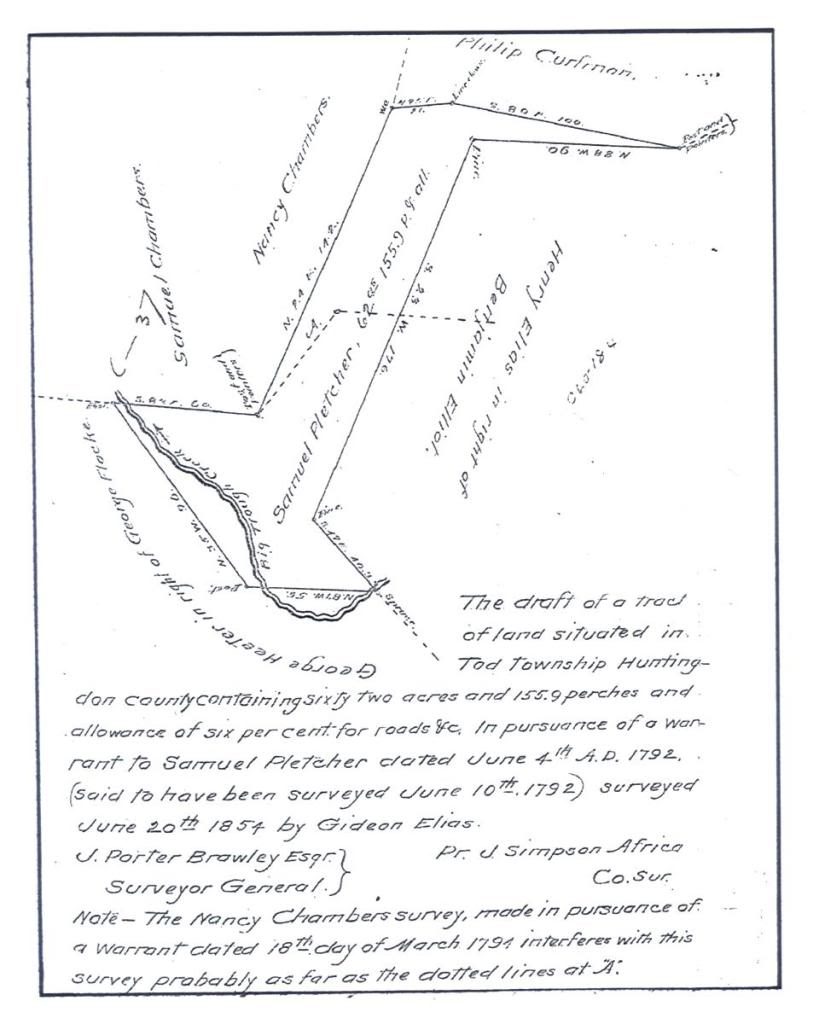

The draft below was for a 62 acre piece of land Samuel owned in Huntingdon County. The survey was done in 1792. I don’t know if this is part of the ground under the reservoir.

We left Howard without being able to speak with Carolyn Hollar. We would like to speak with her on the phone.

The last person we spoke with was the town undertaker. He described the part of the Schenck Cemetery where we would find the Pletchers. This old portion of the cemetery was moved from the old Pletcher Cemetery that is now under water.

While we found quite a bit of information, it was disappointing to see the Howard area altered so greatly by the building of the dams. Much of the original valley is under water, and the early cemetery was moved to a location on 150 west of Howard.

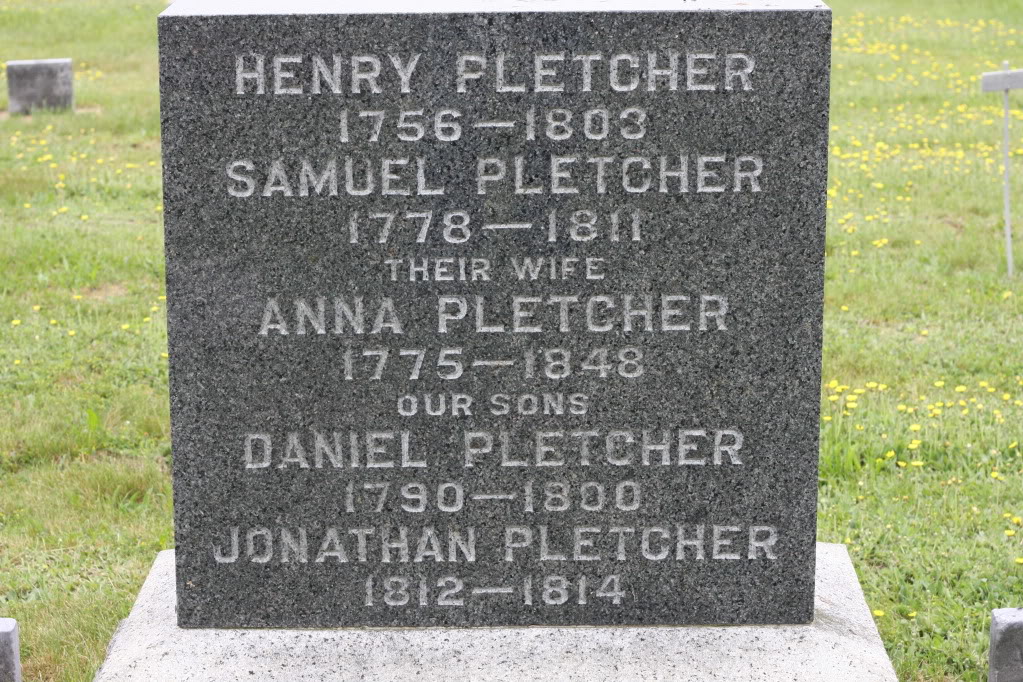

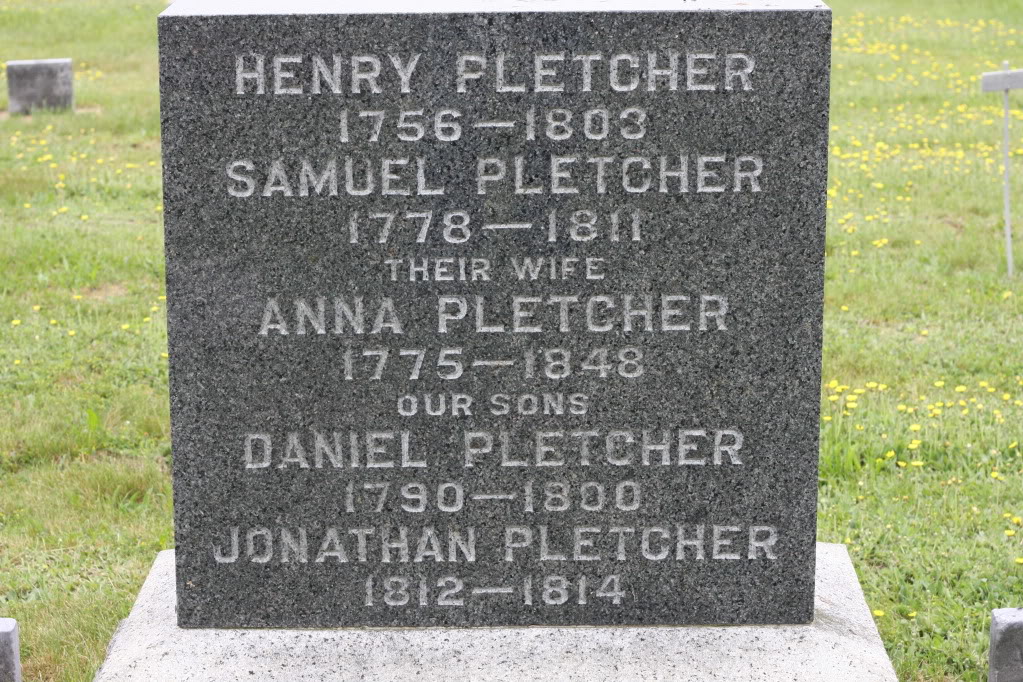

We went to the cemetery and took photos of any Pletcher stone we could find. There were a number of second generation children and of course Henry. He died of complications from a horse kick in 1803. His son Daniel died at age 10 in 1800, and may have been the first Pletcher buried in the old cemetery.

The caption on this stone may be confusing. Most stones don’t use the phrase “their wife”, however it is correct in this case. When Henry (Generation 1)was killed by complications of the horse kick, He left Anna Schenck Pletcher, his second wife as a widow. She then married her nephew, Samuel Pletcher (Generation 2), the son of Samuel Pletcher (Generation 1).

Galion, OH – Friday, May 29

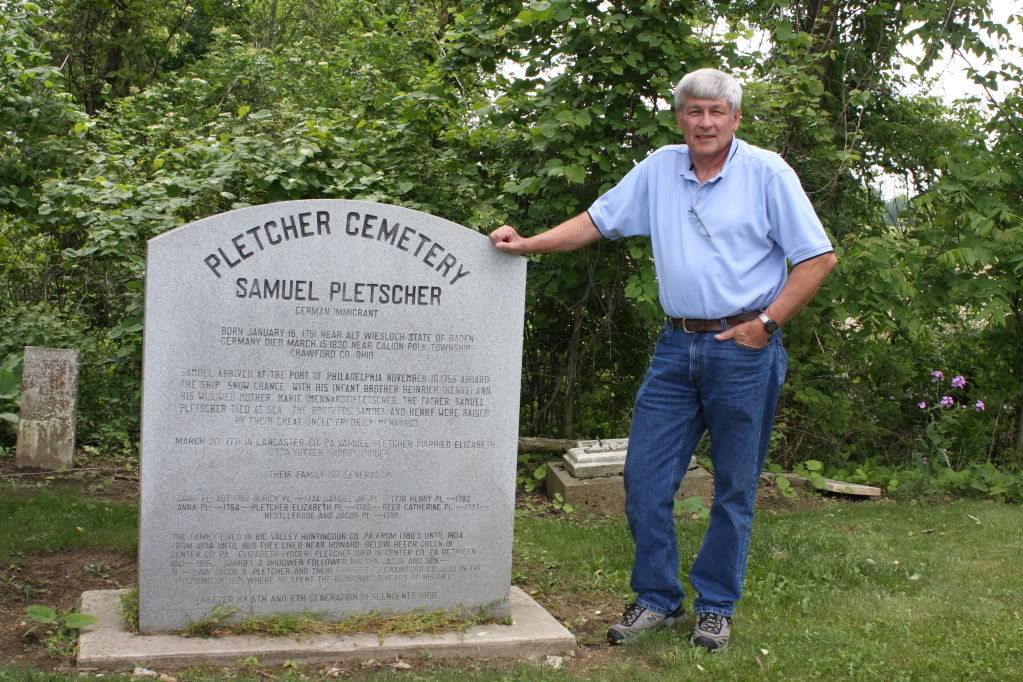

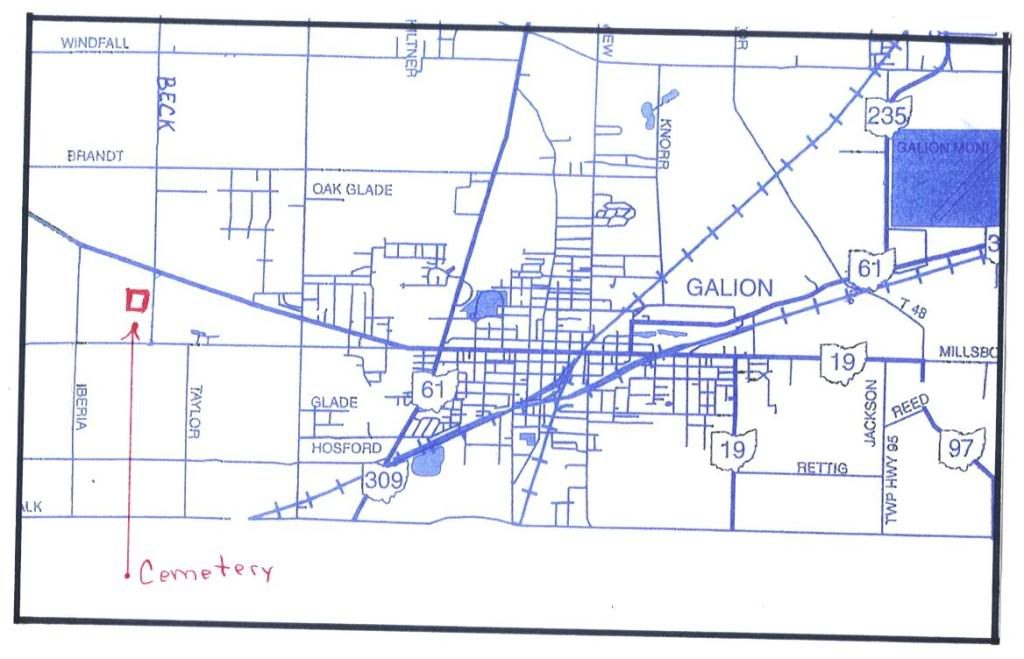

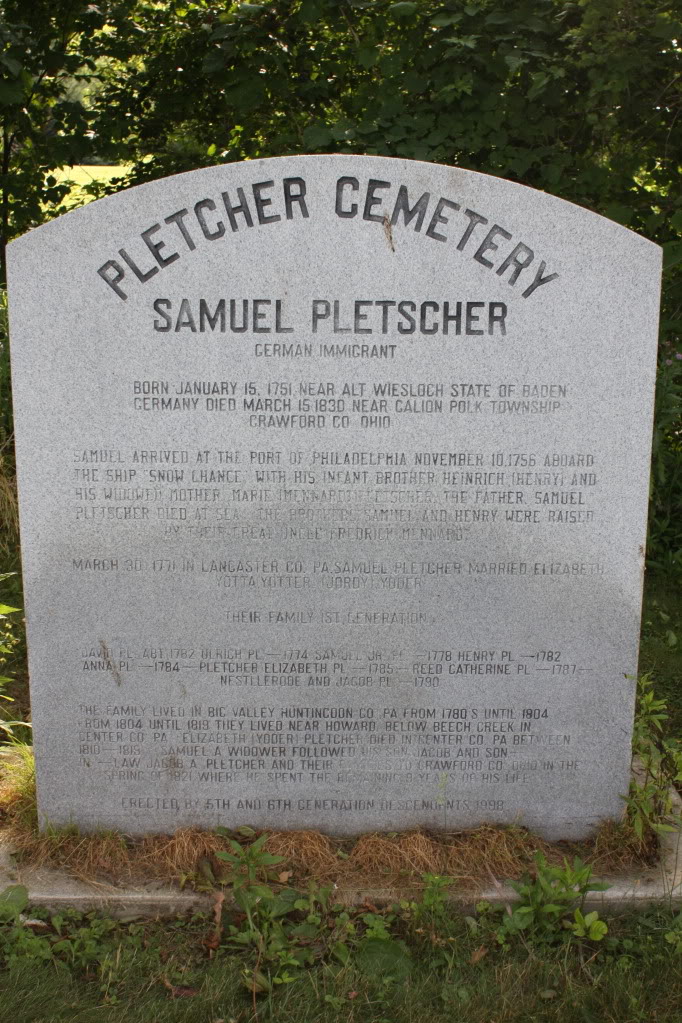

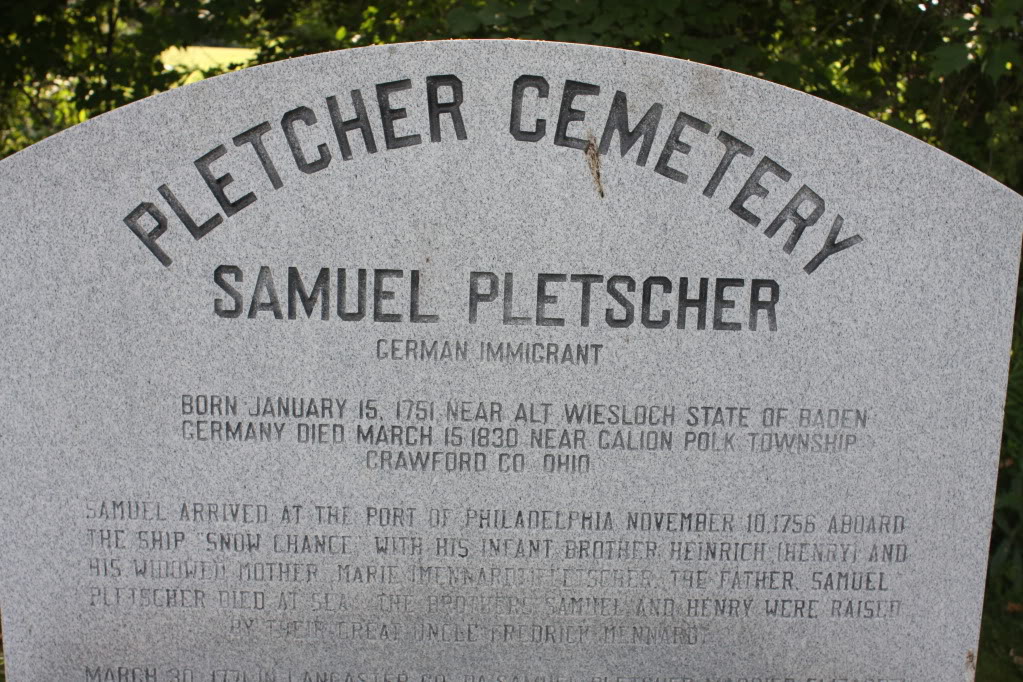

In Galion, Ohio our luck changed from bad to good. Our first stop was Chamber of Commerce tourist information. We asked about the Pletcher Cemetery and were given directions to the Whetstone Cemetery. We were told that this is the cemetery we were looking for. As we left they told us that the town library might have more information.

When we asked if anyone in the library knew of the Pletcher Cemetery, one lady said that she did. We were lucky, because she was there only one day a week. She found a book listing Ohio cemeteries and we ended up with a map to the cemetery and a listing of the grave stones. We took her name and address for future study.

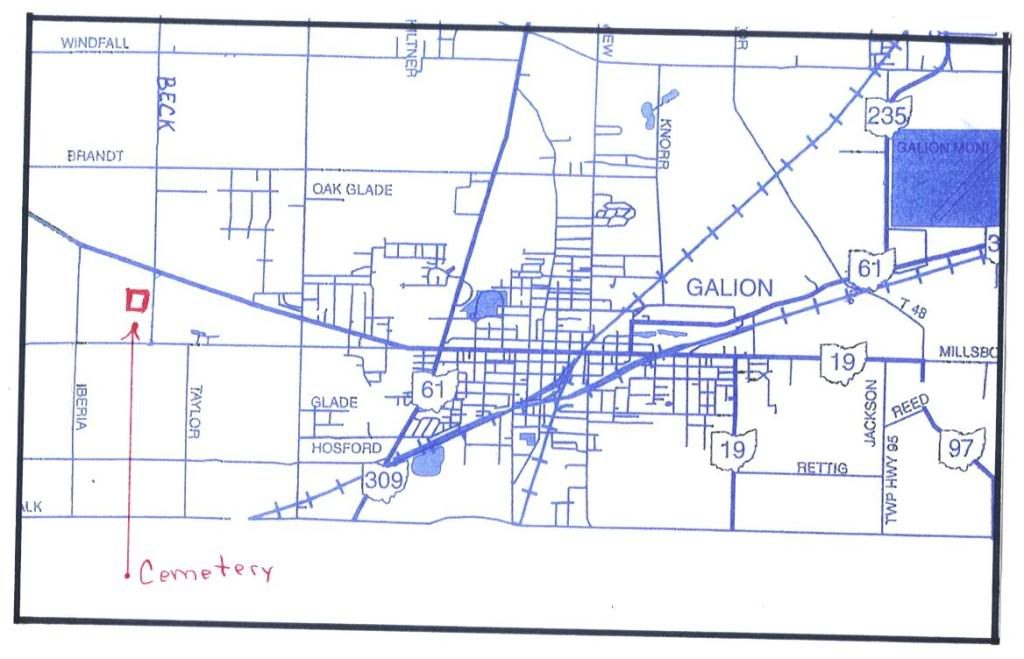

This map shows where to find the Pletcher Cemetery. After you turn unto Beck Rd look to the right. You can see the stones from the road.

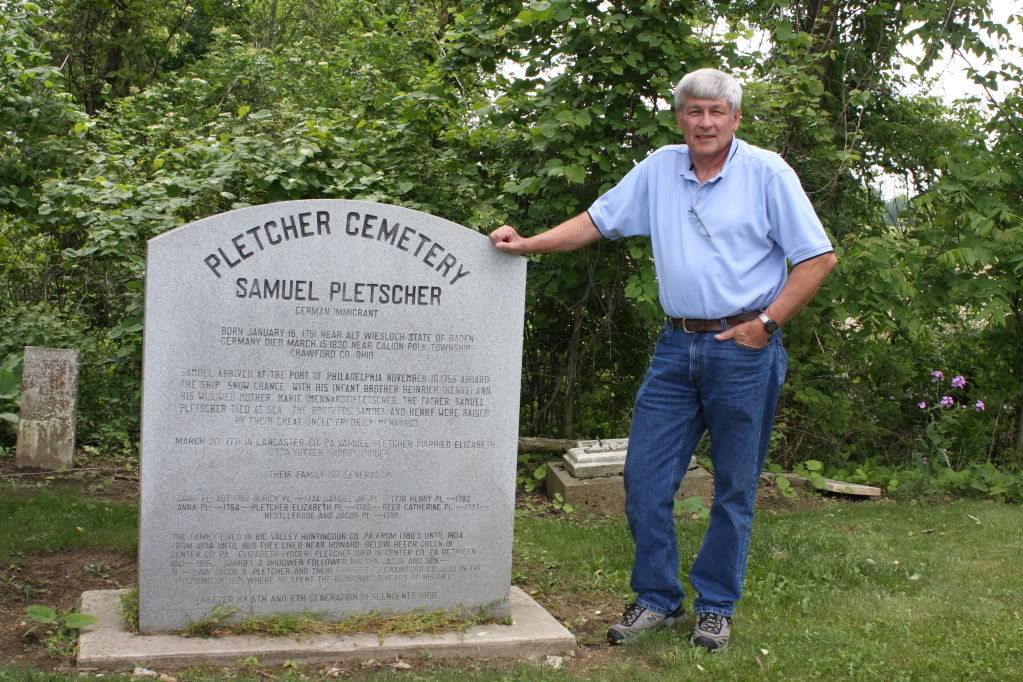

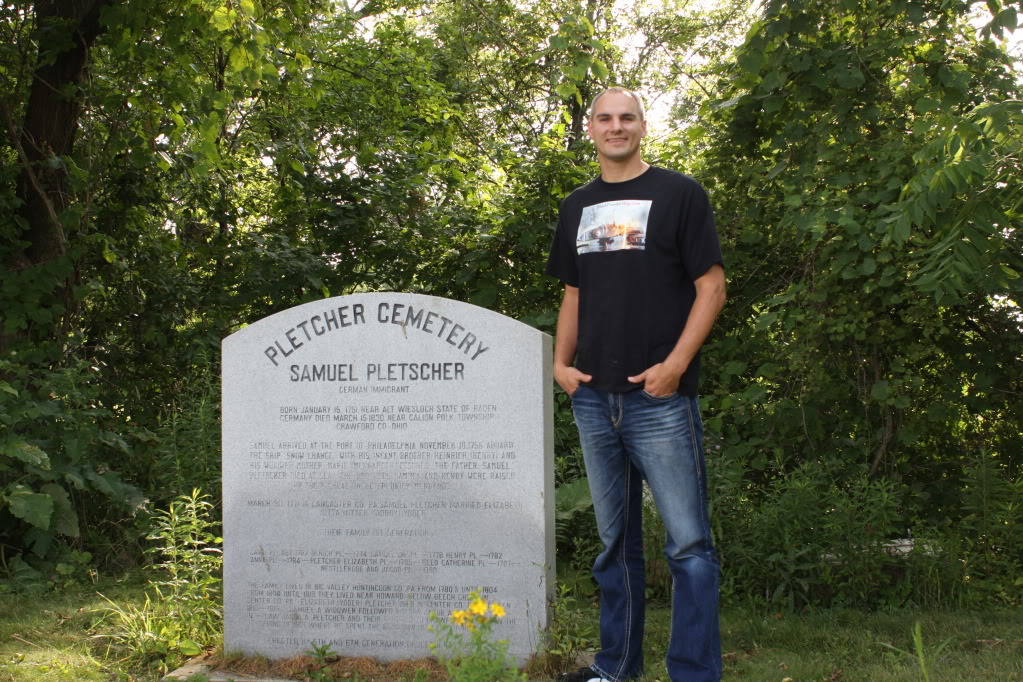

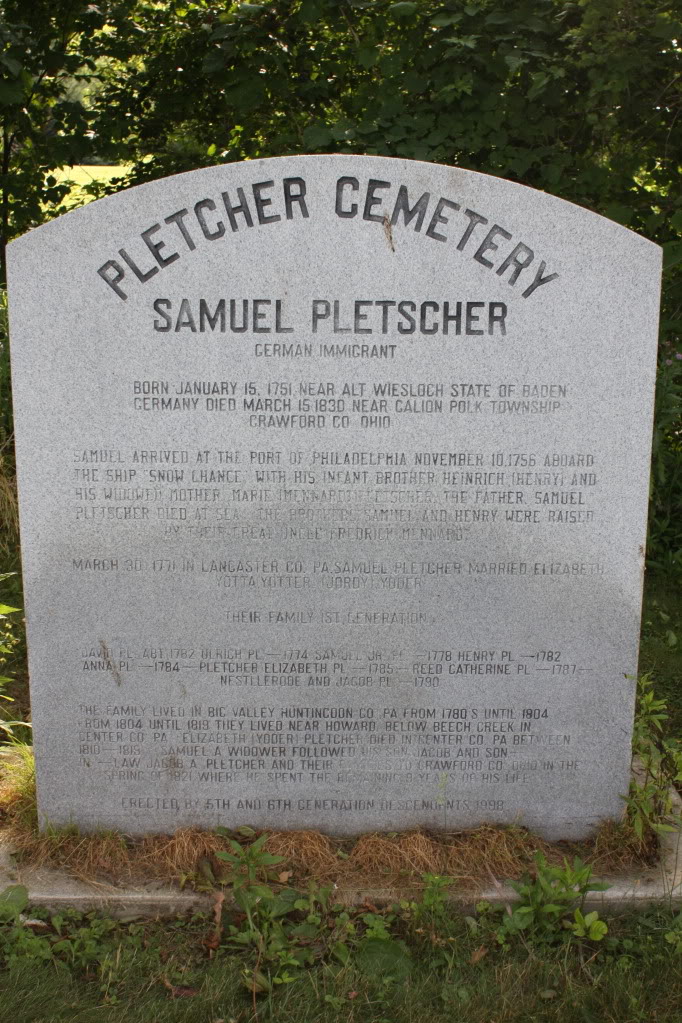

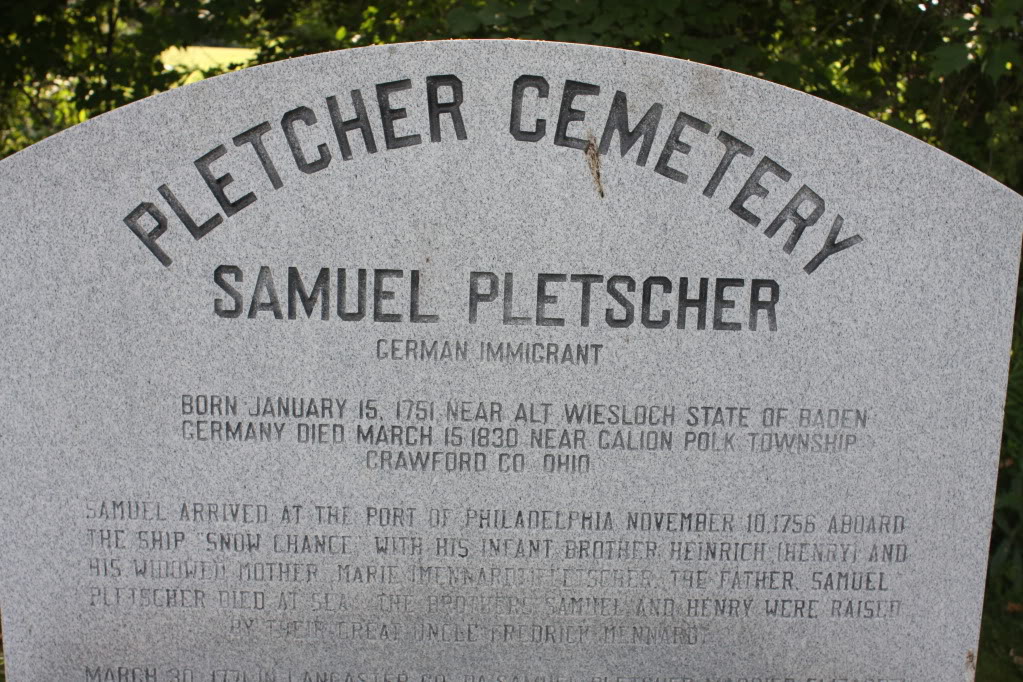

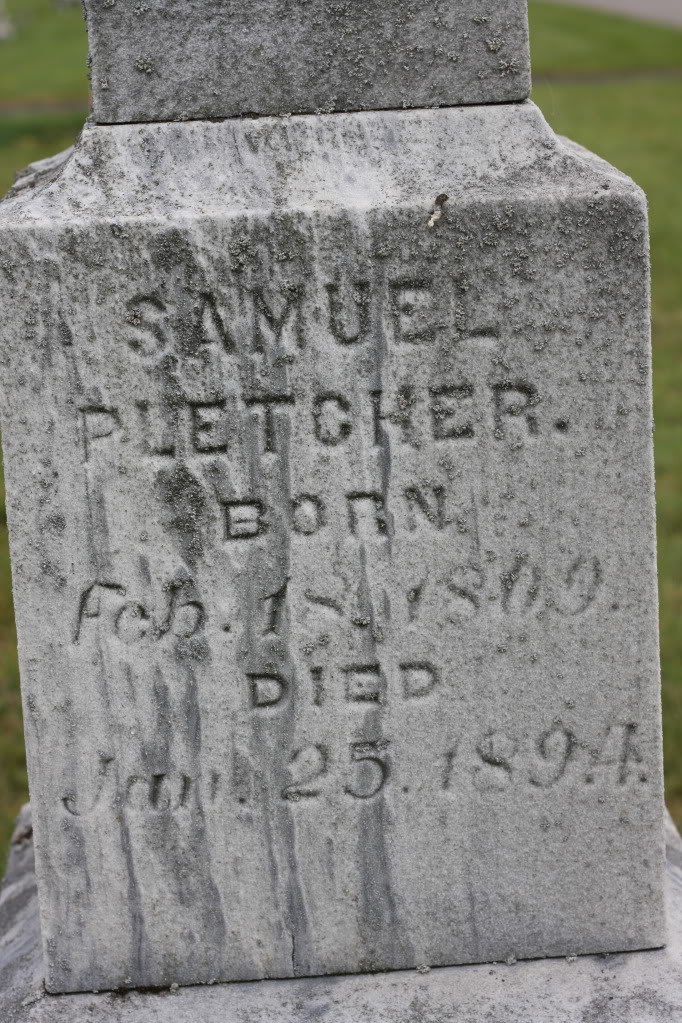

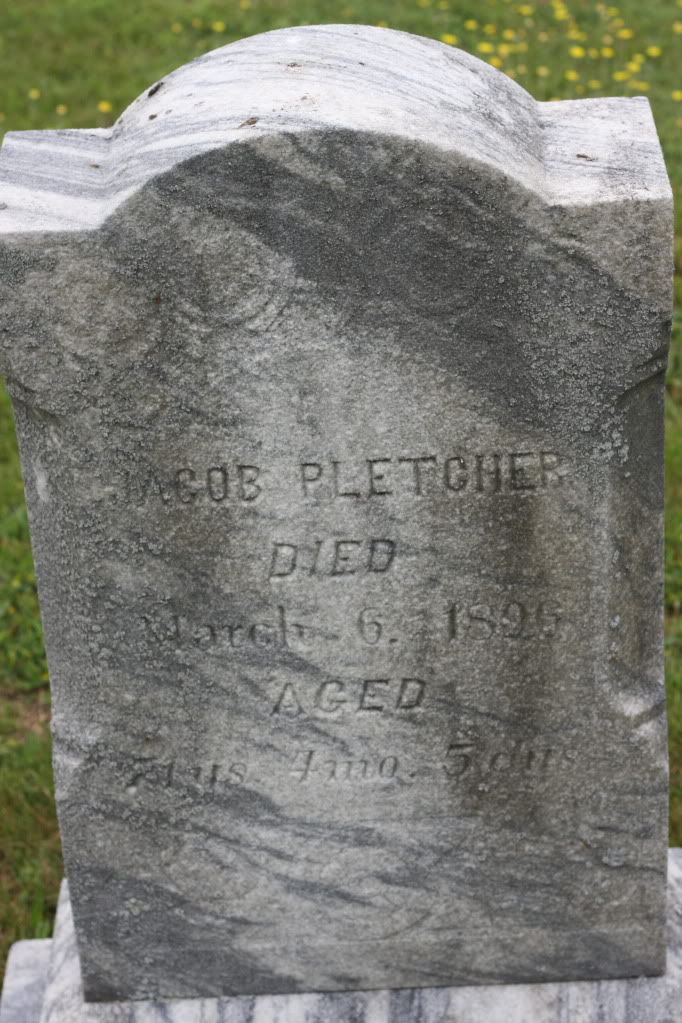

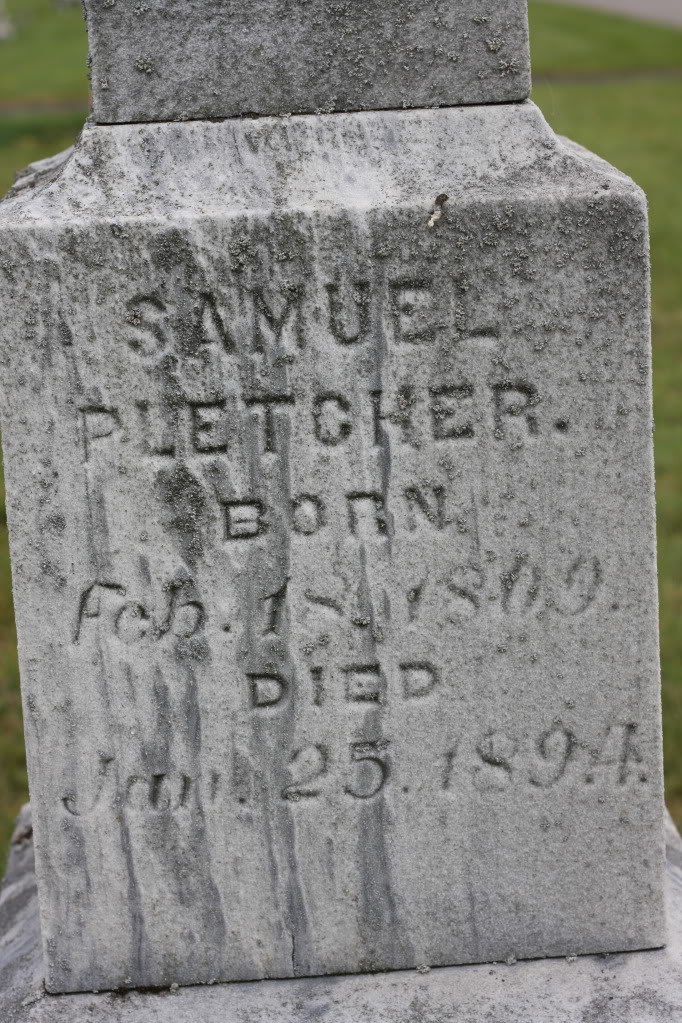

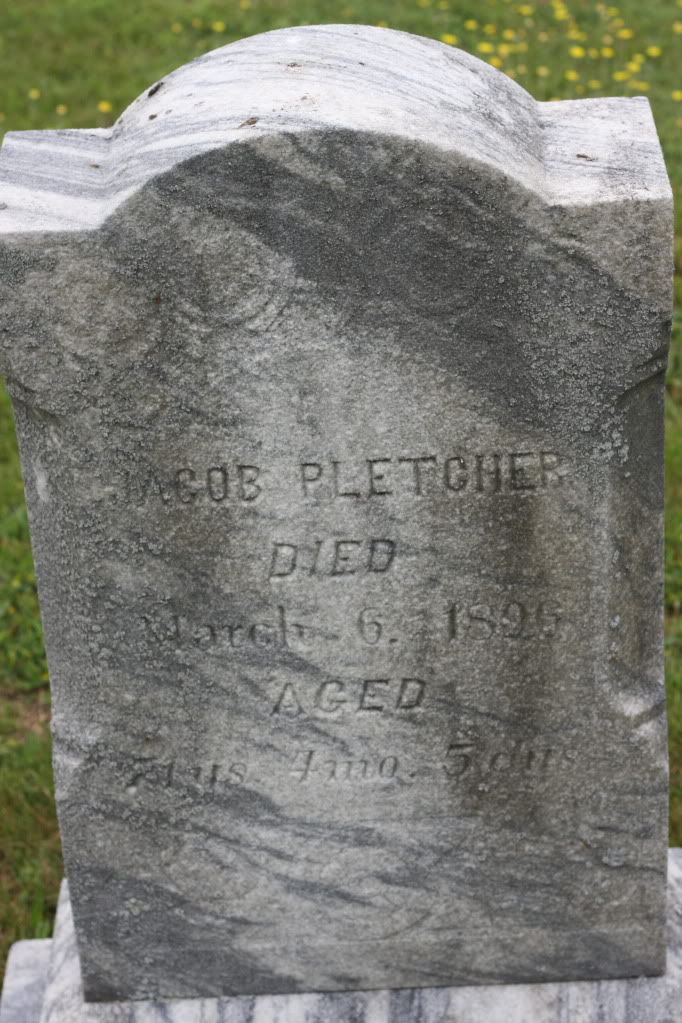

We drove to the farm and asked permission to visit the cemetery. I also asked if the barn was original and was told it was. We found Samuel’s grave stone as well as Jacob N., his wife, and Henry W., the last Pletcher owner.

On our way out we took photos of the barn. It was the only building we saw on the trip that was built by Pletchers.

2011 Addition

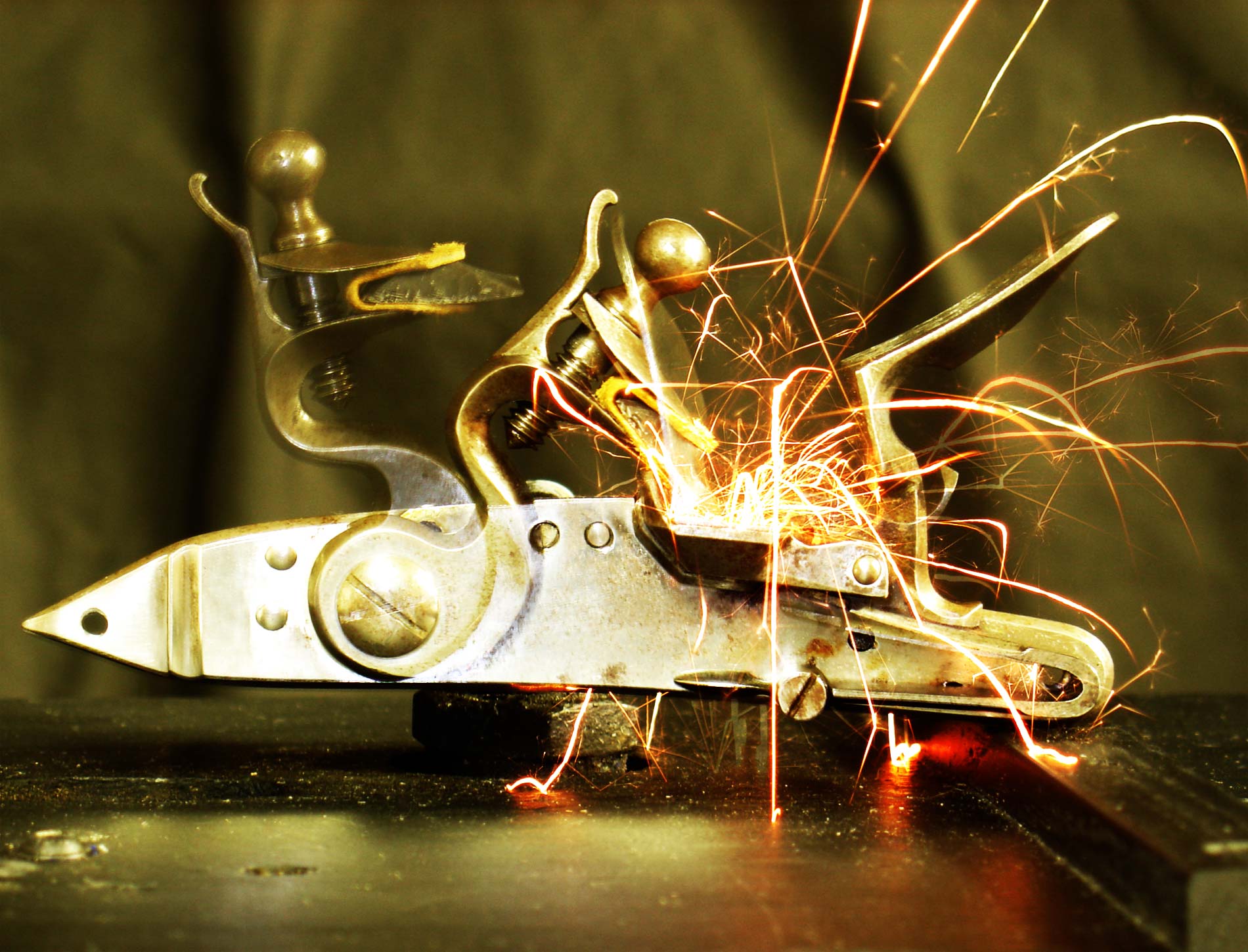

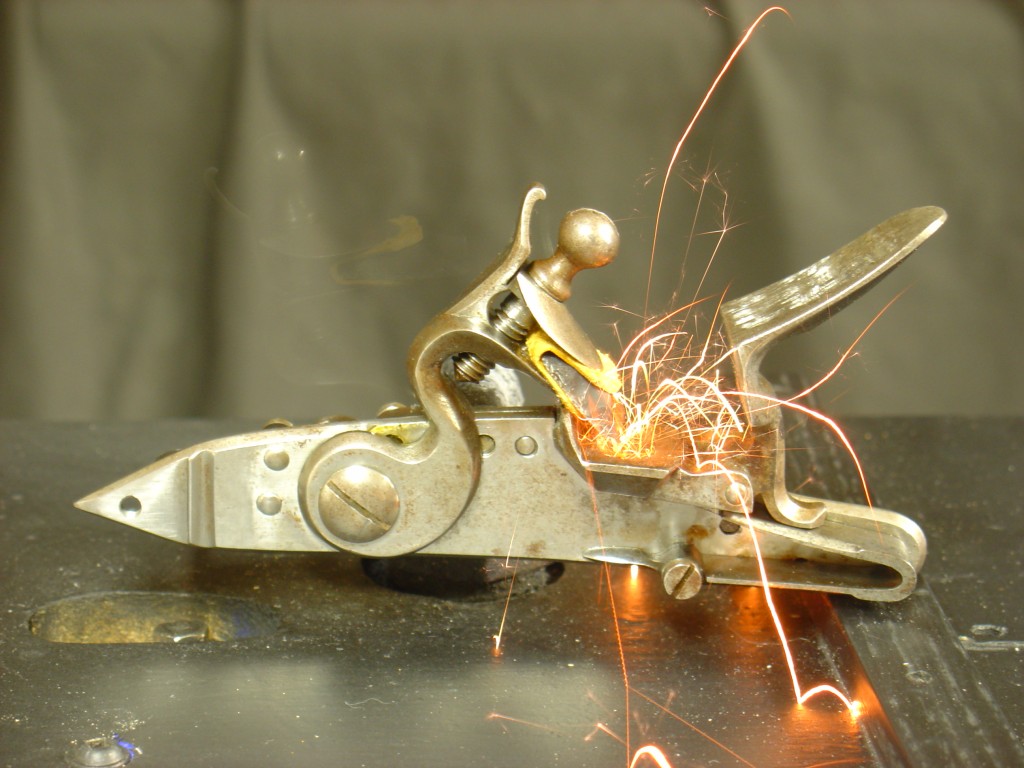

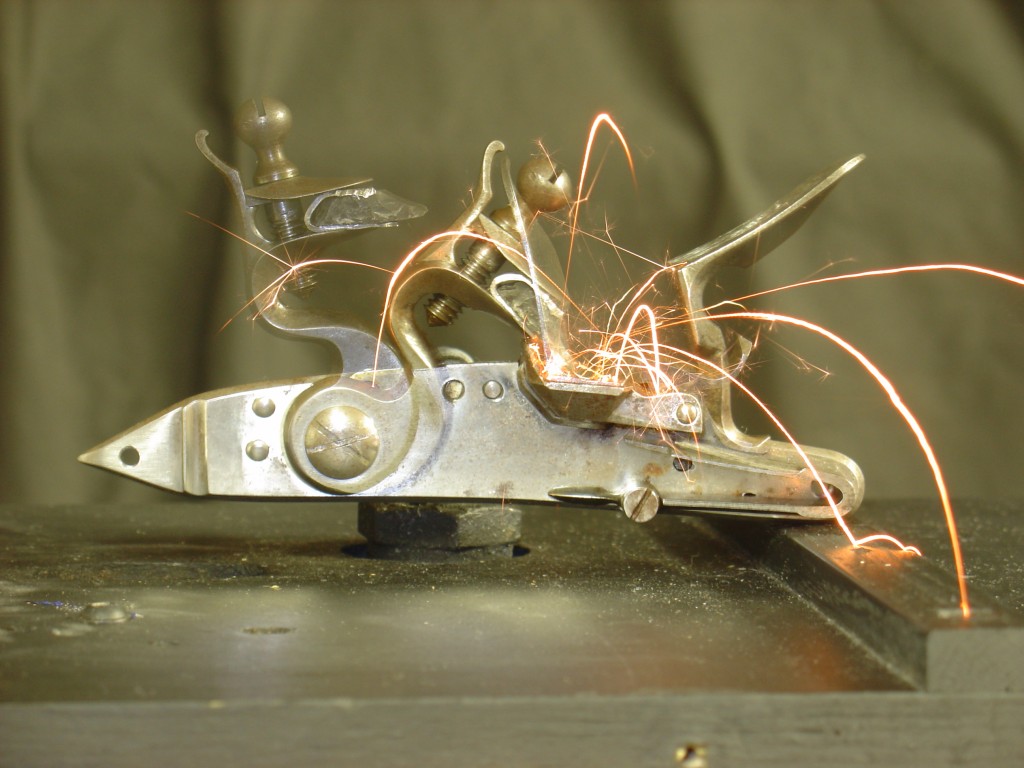

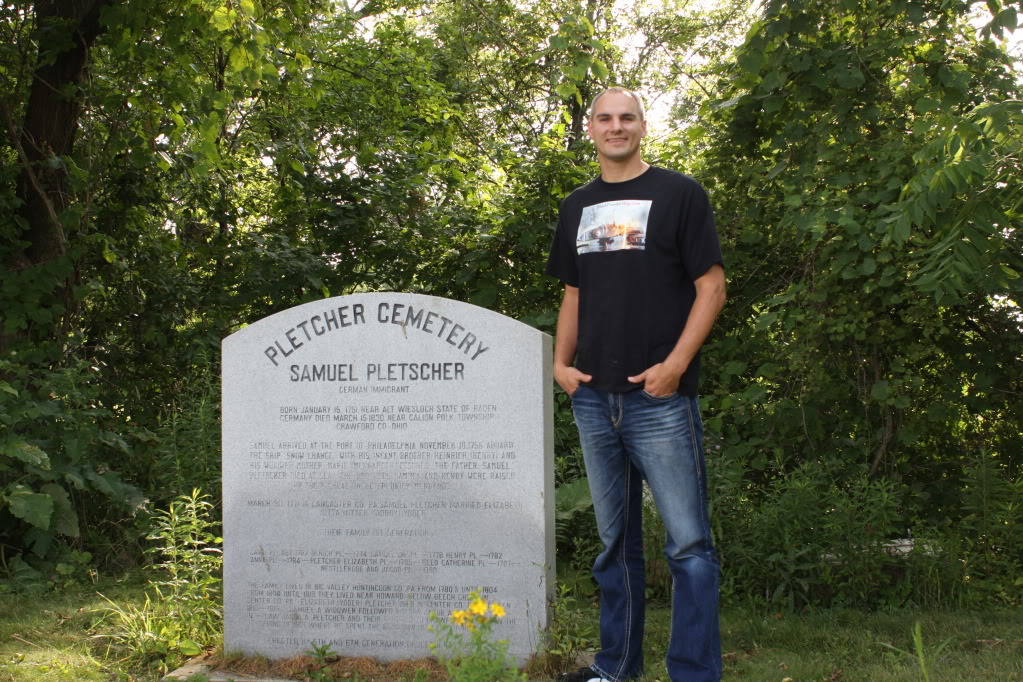

In June 2011, Kevin went with me to a black powder presentation in Ohio. On our return, we stopped at the Pletcher cemetery to take a few extra photos. I wanted to have pictures of Kevin next to his great, great, great, great, great grandfather’s grave stone.